Cogeneration means combined heat and power (CHP). Cogeneration is defined as the sequential generation of two different forms of useful energy from a single primary energy source. It produces electricity and thermal energy at high efficiencies using a range of technologies and fuels. Cogeneration used for many years all over the globe across different industries in several forms like steam boilers and steam turbines, gas turbines, reciprocating engines, and heat recovery systems. In Cogeneration, the fuel is used first to drive the prime mover to generate electricity and produce heat. The heat is then used to boil water and generate steam. Some of the steam is used to support a process while the remaining steam is used to drive a steam turbine to generate additional power.

Cogeneration is very efficiently helpful by using waste heat recovery technology to capture wasted heat associated with electricity production. Cogeneration systems typically achieve total system efficiencies of 60 to 80%. For micro-cogeneration systems, the main output is heat, with some electricity generation, at a typical ratio of about 6.1 for domestic appliances.

In the case of steam turbines, cogeneration technologies widely commercialized include extraction and backpressure steam turbines. The capital cost to build a cogeneration plant and the size of the plant required to demand a constant load 24/7 for viability and financial advantages, but the main advantage of this type of cogeneration is the long plant life for the steam turbines due to low wear and tear. In steam cogeneration systems the fossil fuels mostly used are coal, oil, and natural gas.

Cogeneration is likely to be most attractive because the requirement of demand for both steam and power is balanced which is consistent with the range of steam. And also power output ratios that can be obtained from only suitable cogeneration. Cogeneration is also most likely to be attractive for a single plant or group of plants that has sufficient demand for steam and power to permit economies of scale to be achieved. Cogeneration also helps peaks and troughs in demand can be managed or, in the case of electricity, adequate backup supplies can be obtained from the utility company.

The ratio of heat to the power required by a site may vary during different times of the day and seasons of the year. Importing power from the grid can make up a shortfall in electrical output from the cogeneration unit and firing standby boilers can also satisfy additional heat demand.

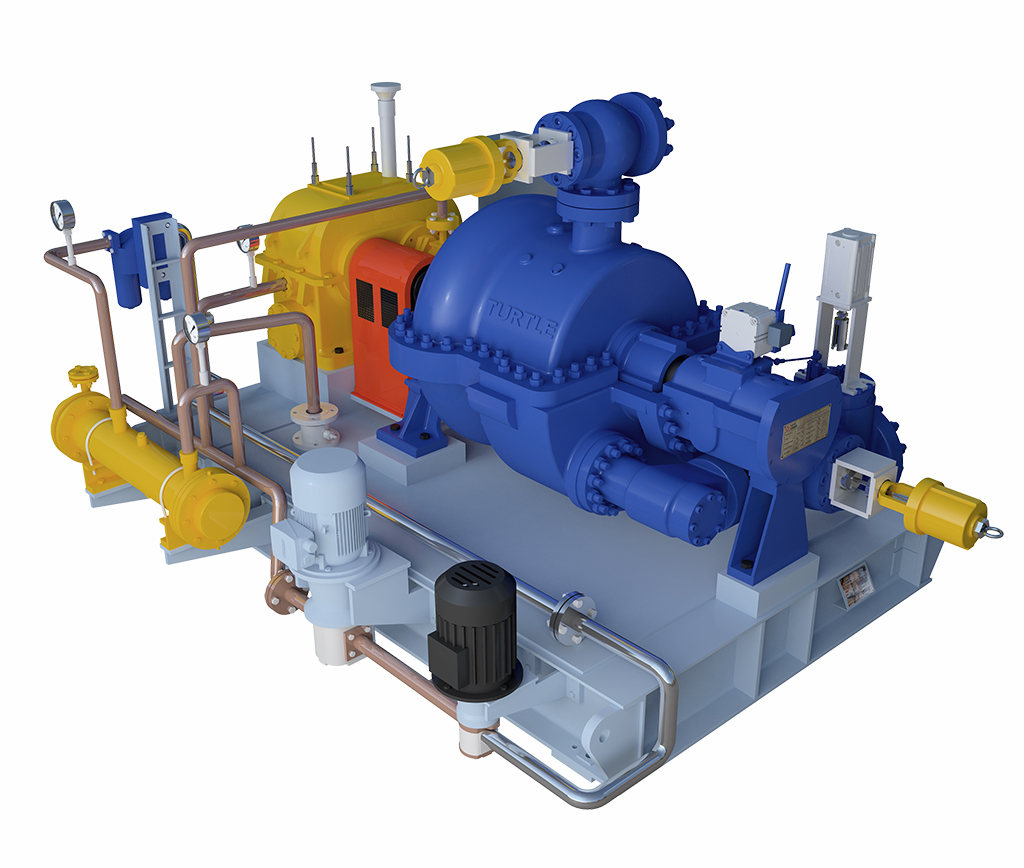

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. Turtle Turbines has been in the business of supplying Steam Turbines for Cogeneration and Micro Cogeneration. Turtle Turbines has supplied numerous Steam Turbine Cogeneration plants across India, South East Asia, and African Countries.