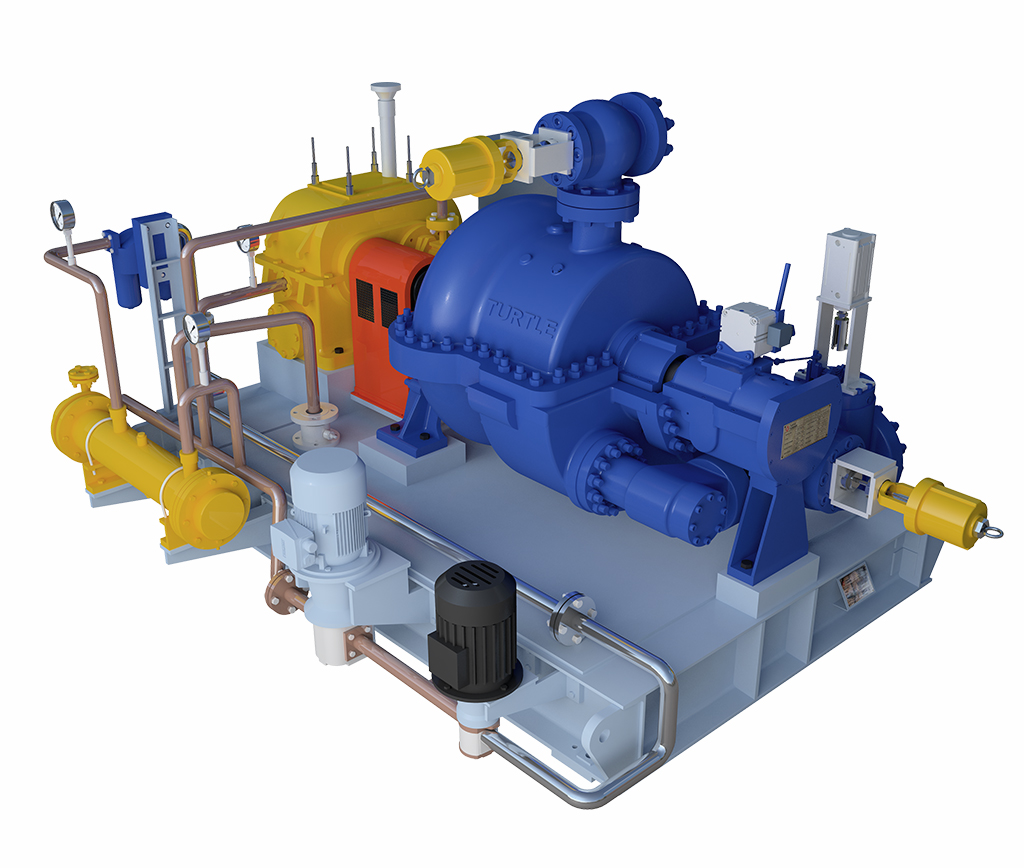

The steam turbine is Equipment used to produce electrical power using steam.

To have a good performance of the turbine it needs to be operated properly. Below are the secrets of successful steam turbine operation

- Steam quality:

Steam turbine operation and performance require the correct steam pressure at the turbine inlet and high steam quality (steam without condensate entrapment) to ensure high turbine reliability. Low-quality steam reduces the steam turbine efficiency and causes erosion of steam turbine components (blades, governor valves, blading, and nozzles). - Lubrication system:

Lubrication of the rotating parts is very important to reduce the friction and wear and tear of the components. A proper lubrication system needs to be provided for the steam turbine which includes MOP, AOP, and EOP. Ensure the required oil level in the lube oil tank. The lubricating oil should be kept at the appropriate operating temperature as possible this is to be achieved by providing an oil cooling system.

3 Bearing maintenance: Bearings of the steam turbine shaft should be checked regularly. Desired pressure needs to be maintained in the lubrication system to circulate the oil through bearings and other passages.

4 cleanliness of the steam turbine room:

The steam Turbine room must be clean properly all the instrumentation needs to check for their proper functioning. Instruments are to be calibrated at regular intervals. Instrument air should be free of dirt and oil.

5 general maintenance of the turbine.

Steam turbine regular maintenance procedures to be followed on a timely basis to ensure the hazel-free operation of steam turbines

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.