Steam turbines account for more than half of the world’s electricity production in power plants around the world and will continue to be the dominant force in electricity power generation for the foreseeable future. The enhancement of steam turbine efficiency is increasingly important as the urgency to reduce CO2 emissions into the atmosphere is a problem at the forefront of power production. Increasing efficiency in steam turbines, and other components of power plants, will help meet the growing demands for electricity worldwide while reducing harmful greenhouse emissions.

Steam turbines are used in coal-fired, nuclear, geothermal, natural gas-fired, and solar thermal power plants. Also, steam turbines are increasingly needed to stabilize fluctuating power demands from solar and wind power stations as renewable energy sources grow worldwide. The current emphasis on steam turbine development is for increasing efficiency, mainly by increasing steam turbine capacity, as well as increasing operational availability, which translates to rapid start-up and shut down procedures.

The efficiency of steam turbines increases with increasing inlet temperature and inlet pressure; however, limits are imposed in the case of Small to Medium sizes steam turbines due to the limited steam flows and thus the related boiler design parameters. There are many methods to improve the thermal efficiency of a steam cycle, in the case of small to medium size steam turbines, but a balance must be reached between efficiency improvement and economical costs with each design. It is also important to consider the complexity owing to increasing steam pressure and temperature beyond a reasonable level.

Usually, it pays in terms of overall all cost-benefit if the inlet pressures and temperature are in the range of about 67 bar and 495 deg C for Steam Turbines of capacity range up to 5 MW. This is considered to be a sweat spot towards reasonable investment cost on one hand and the efficiency on other.

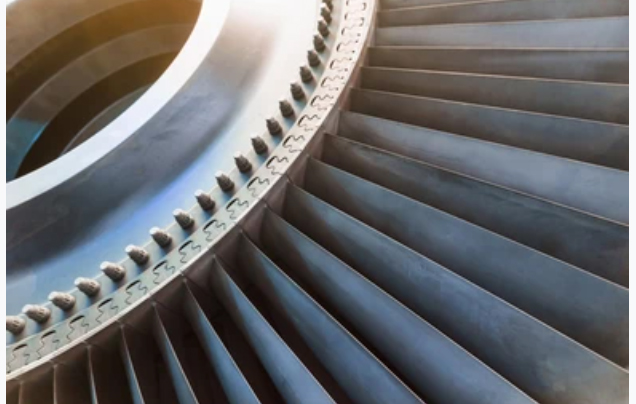

Certain Steam Turbine technologies are intrinsically superior in terms of efficiency compared to others. Reaction Steam Turbine technology offers better efficiency than impulse steam turbine technology. However, there are other limitations when such technology is applied to Industrial Steam turbines with varying steam flows. Hence a balance between the selection of turbine technology is very important to ensure a practical steam turbine installation in the small to medium range.

Turtle Turbines manufactures steam turbines considering all these aspects while configuring the basic steam turbine design. This has resulted in a balanced Steam Turbine design that provides the best in its class efficiency without compromising the operational challenges in Industrial Steam Turbines.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.