Jaggery is a form of unrefined sugar and is obtained by boiling raw sugarcane juice till it almost solidifies. Jaggery making is a simple process comprising crushing of sugarcane for juice extraction, filtration, and boiling of juice for concentration and then cooling and solidifying to give jaggery blocks. The juice is extracted in a conventional crusher this is then filtered and boiled in shallow iron pans.

The need for Steam turbines is derived since jaggery making is shifting from traditional methods to Vacuum Pan Boiling and other methods like juice boiling crushing in the sugar industry. After crushing the Sugarcane Bagasse is readily available. In the process, steam is required around 120 Deg C which is at 1.2 to 1.5 kg/cm2 (g) pressure. A high-pressure boiler of 32 kg/cm2 (g) and 380 deg C can be a good option for a jaggery plant of more than 250 TCD. For a 100 to 200 TCD plant, medium pressure capacity boilers can be used.

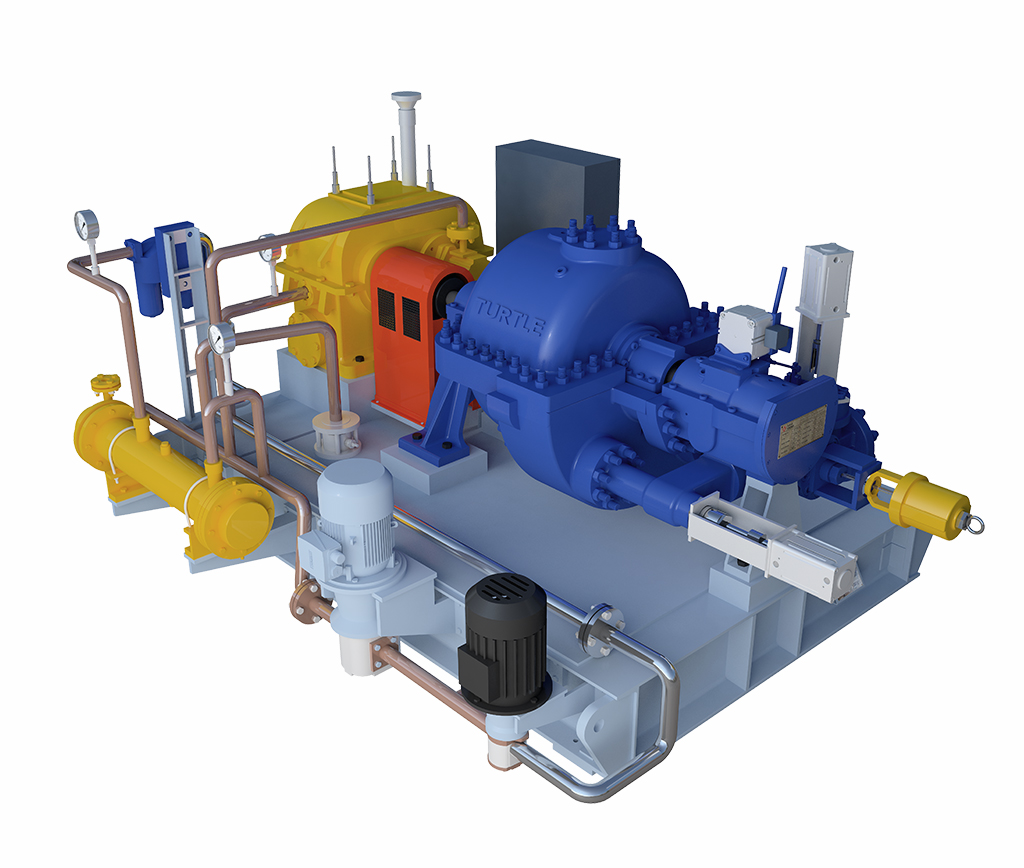

Which can be sent through a steam turbine and further sent to process for jaggery making by steam boiling method. Steam boiling is a step towards modernization of jaggery making. The steam generated is first used for Power Generation in the Steam Turbines and then used for process heating. Turtle Turbines has supplied several Steam Turbines for the jaggery industry making them self-sufficient on power and heat. Power generated by using high-pressure boilers normally fulfills the plant’s total electrical load and power generated with medium pressure saturated boiler with Grid Sync Option can meet the total electrical demand.

The jaggery plant can be run smoothly just like a sugar plant by using a boiler and Turbine in the plant. Using the already available bagasse can reduce the cost drastically.