01. WHAT WE DO

Reshaping Green Energy for the Industry! Steam Turbine Manufacturer in India

We empower Industries to generate Green Electrical Energy along side meeting Heating requirements. Our Cogeneration Technologies enhance system efficiencies up to 80%. Higher efficiencies lead to reduced global warming.

0

MW of Green Energy

Generated

0

Tons of Carbon Emission

Mitigated

0

MW of Green Energy

Generated

0

Tons of Carbon Emission

Mitigated

Reshaping Green Energy for the Industry! Steam Turbine Manufacturer in India

We empower Industries to generate Green Electrical Energy along side meeting Heating requirements. Our Cogeneration Technologies enhance system efficiencies up to 80%. Higher efficiencies lead to reduced global warming.

0

MW of Green Energy

Generated

0

Tons of Carbon Emission

Mitigated

0

MW of Green Energy

Generated

0

Tons of Carbon Emission

Mitigated

MicroTurbines

MicroTurbines

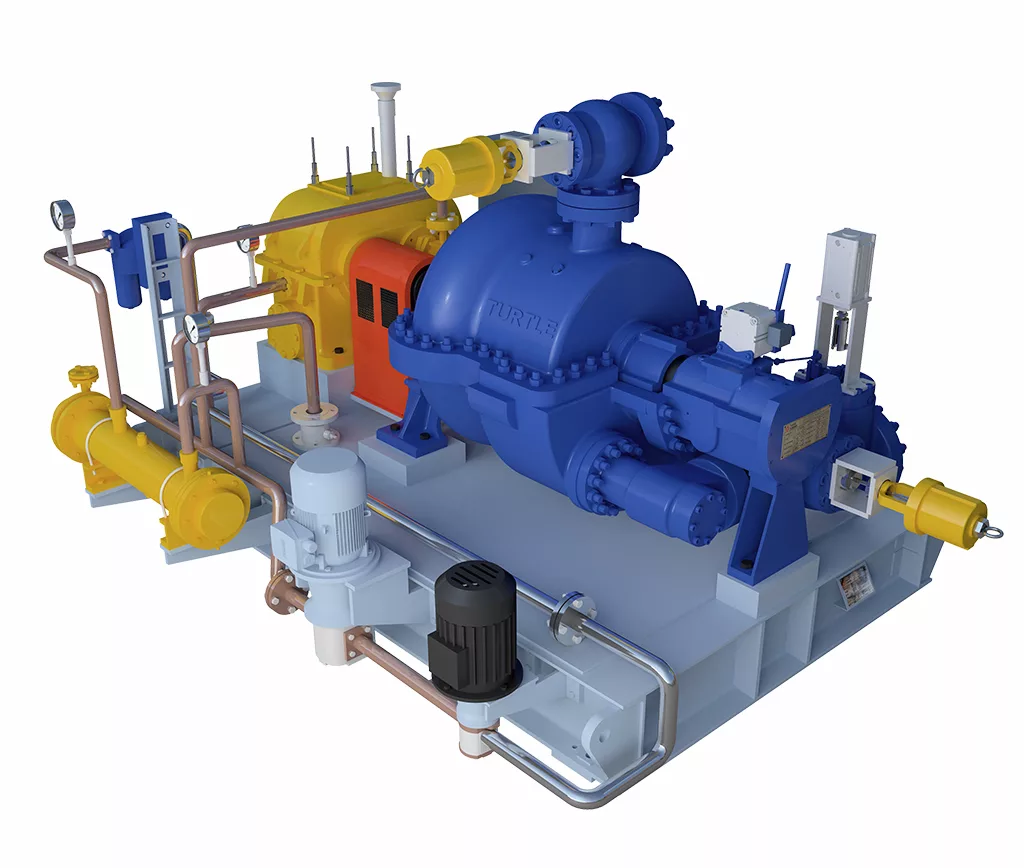

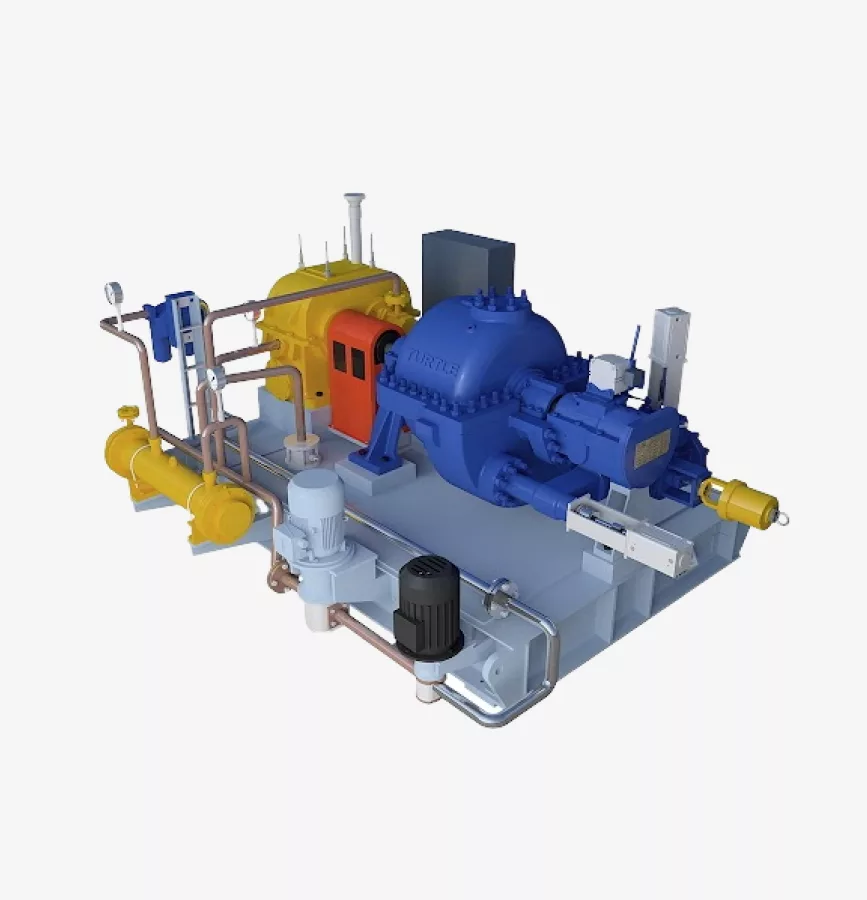

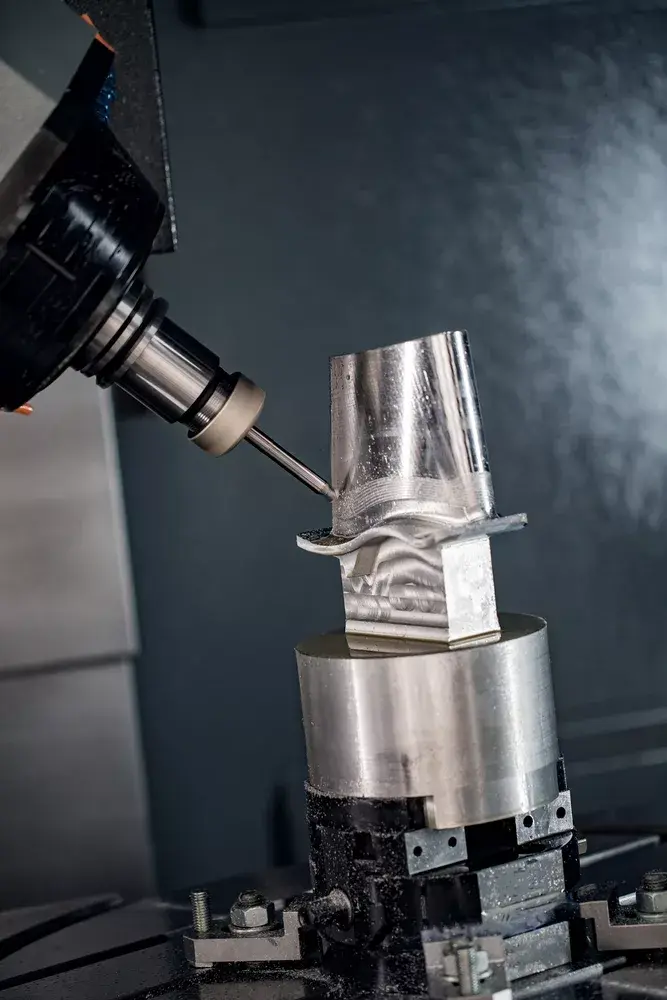

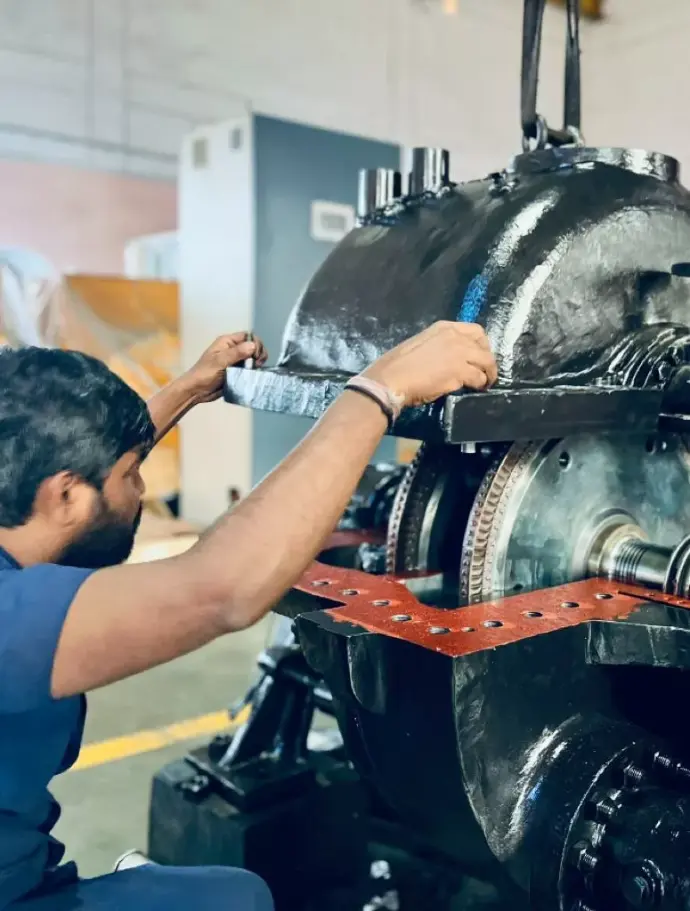

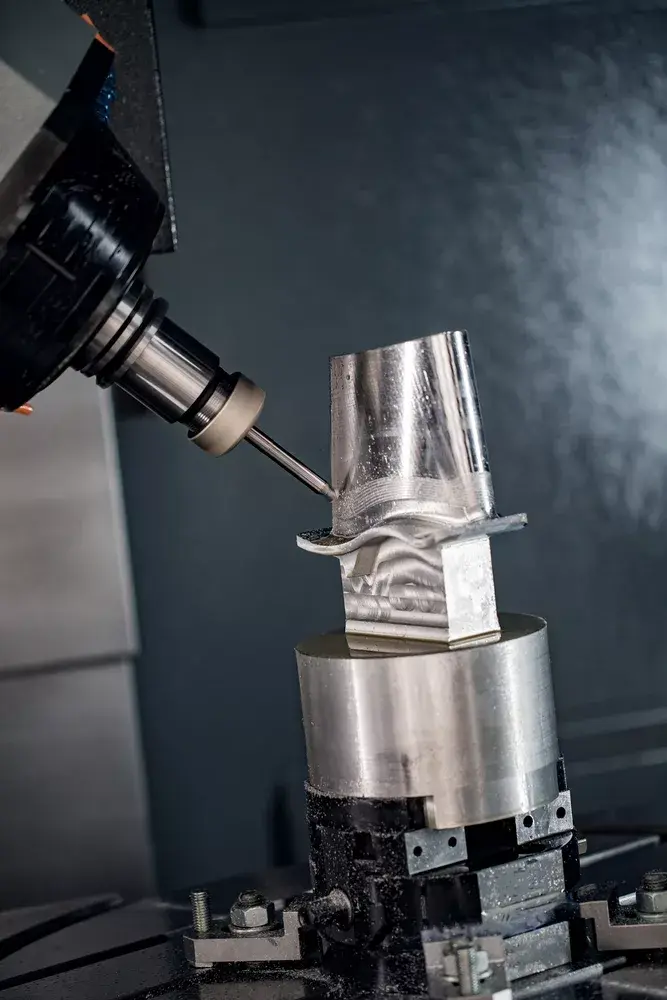

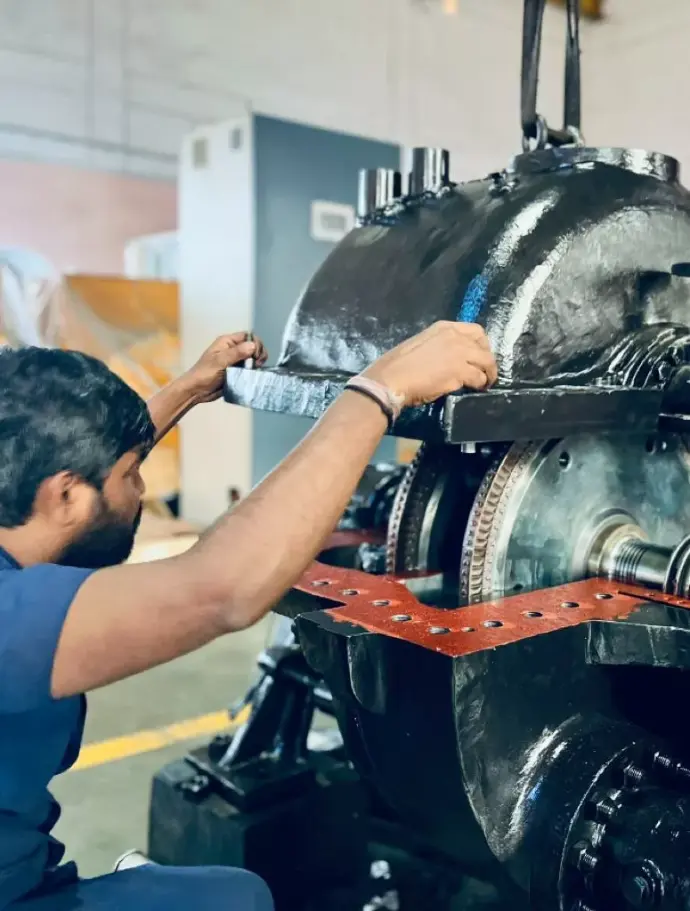

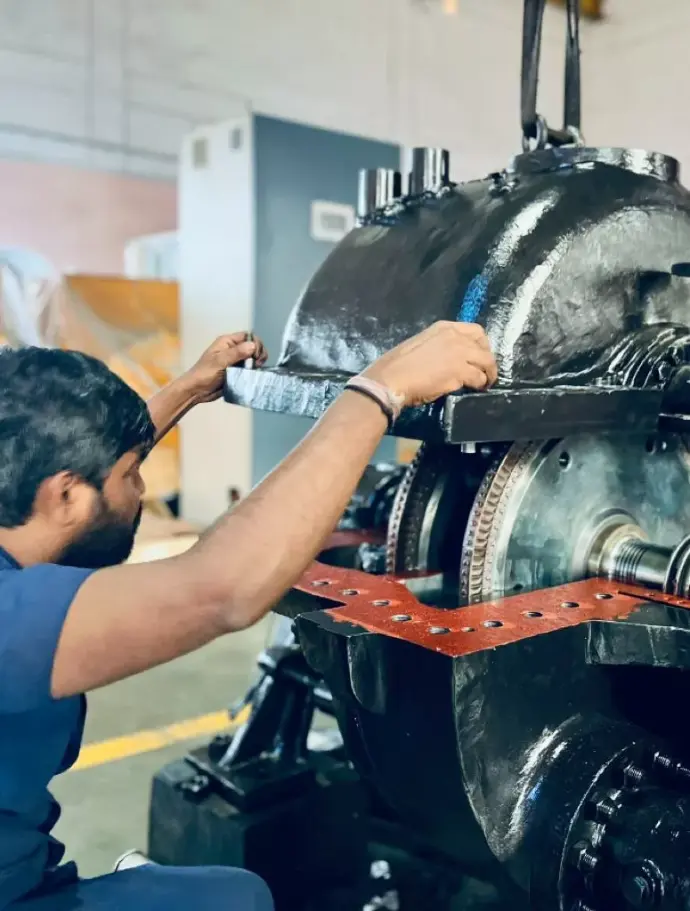

Steam Turbine Manufacturer in India since 20 Years

Turbines are precision manufactured on modern machines. Special multiplane balanced turbine rotors lead to super smooth operation. Every Turbine is assembled with care for perfection.

Less Vibrations

RELIABLE

Less Lube Oil

ROBUST

Less Manpower

INTELLIGENT

Less Vibrations

RELIABLE

Less Lube Oil

ROBUST

Less Manpower

INTELLIGENT

03. OUR CONTRIBUTION

Steam Turbine Manufacturer in India since 20 Years

Turbines are precision manufactured on modern machines. Special multiplane balanced turbine rotors lead to super smooth operation. Every Turbine is assembled with care for perfection.

Less Vibrations

RELIABLE

Less Lube Oil

ROBUST

Less Manpower

INTELLIGENT

Less Vibrations

RELIABLE

Less Lube Oil

ROBUST

Less Manpower

INTELLIGENT

03. OUR CONTRIBUTION

APPLICATIONS

Our Installations

APPLICATIONS

Our Installations

MicroTurbine vaporpower

300 kW for Milk Processing Plant in India

MicroTurbine vaporpower

150 kW for Soap Detergent Plant in India

MicroTurbine vaporpower

30 kW for Food Processing Plant in Philippines

Compact CAPTIVE TUSKER

Aux Control System for Sulphuric Acid Plant in India

Mini COGEN TORUS

TurboSmart Turbine Control System for Palm Oil Refinery in Philippines

Mini COGEN TORUS

1 MW for Wood Processing Plant in Indonesia

Mini COGEN TORUS

710 kW for a Tea Factory in Kenya

Mini COGEN TORUS

925 kW for Paper Plant in India

Mini COGEN TORUS

750 kW for Jaggery Plant in India

Mini COGEN TORUS

350 kW for Food Antioxidents Plant in India

MicroTurbine vaporpower

300 kW for Milk Processing Plant in India

MicroTurbine vaporpower

150 kW for Soap Detergent Plant in India

MicroTurbine vaporpower

30 kW for Food Processing Plant in Philippines

Compact CAPTIVE TUSKER

Aux Control System for Sulphuric Acid Plant in India

Mini COGEN TORUS

TurboSmart Turbine Control System for Palm Oil Refinery in Philippines

Mini COGEN TORUS

1 MW for Wood Processing Plant in Indonesia

Mini COGEN TORUS

710 kW for a Tea Factory in Kenya

Mini COGEN TORUS

925 kW for Paper Plant in India

Mini COGEN TORUS

750 kW for Jaggery Plant in India

Mini COGEN TORUS

350 kW for Food Antioxidents Plant in India

05. HOW IT WORKS

Cogeneration,

Simplified!

Cogeneration,

Simplified!

At Turtle Turbines, we believe a Seamless Solution will benefit our Customers. Our Customers can focus on their main Business while we help them generate Green Energy.

With well defined business processes right from understanding your requirements to after sales care, a complete solution is delivered.

Understand

Experienced Application Engineers understand your Heat and Power requirements

Solution

An Optimum Solution is developed to suite your Heat & Power Requirement

Supply

On your order, equipment are supplied to match the required specifications

Install & Care

Drawings for Installation Guidance and supervision. Care & Support for O&M.

Understand

Experienced Application Engineers understand your Heat and Power requirements

Solution

An Optimum Solution is developed to suite your Heat & Power Requirement

Supply

On your order, equipment are supplied to match the required specifications

Install & Care

Drawings for Installation Guidance and supervision. Care & Support for O&M.

What Our Customers Say

We appreciate the technical abilities and prompt delivery as committed by Turtle Turbines. The Steam Turbine Generator is aesthetically simple and beautiful. The whole Installation looks neat and beautiful. We are pleased with the overall performance of the STG unit and Turtle Turbines team.

Sandesh Borwankar

DGM, Engineering Godrej Consumer Products Limited

Kona Sreeramamurthy

Premier Distillers Ltd.

A S Dukane

Global Sr. Vice President, Camlin Fine Sciences, India

Impressed with performance of this machine, we purchased another 600 kVA steam turbine during 2009 and another two steam turbines of 350 kVA and 1250 kVA during 2017 from Turtle Turbines. All these STGs are working satisfactorily and we wish Turtle Turbines a very bright future.

Bajrang Saboo

Shiv Edibles Ltd., Kota

Hugo Douglas-Dufresne

James Finlays, Kenya

What Our Customers Say

We appreciate the technical abilities and prompt delivery as committed by Turtle Turbines. The Steam Turbine Generator is aesthetically simple and beautiful. The whole Installation looks neat and beautiful. We are pleased with the overall performance of the STG unit and Turtle Turbines team.

Sandesh Borwankar

DGM, Engineering Godrej Consumer Products Limited

Kona Sreeramamurthy

Premier Distillers Ltd.

A S Dukane

Global Sr. Vice President, Camlin Fine Sciences, India

Impressed with performance of this machine, we purchased another 600 kVA steam turbine during 2009 and another two steam turbines of 350 kVA and 1250 kVA during 2017 from Turtle Turbines. All these STGs are working satisfactorily and we wish Turtle Turbines a very bright future.

Bajrang Saboo

Shiv Edibles Ltd., Kota

Hugo Douglas-Dufresne

James Finlays, Kenya

06. OUR CUSTOMERS

Customers

06. OUR CUSTOMERS

Customers

07. OUR SERVICES

Services

07. OUR SERVICES

Services

Commissioning

Support

for Statutory

Online Monitoring

Checkups

Breakdown Services

Commissioning

Support

for Statutory

Online Monitoring

Checkups

Breakdown Services