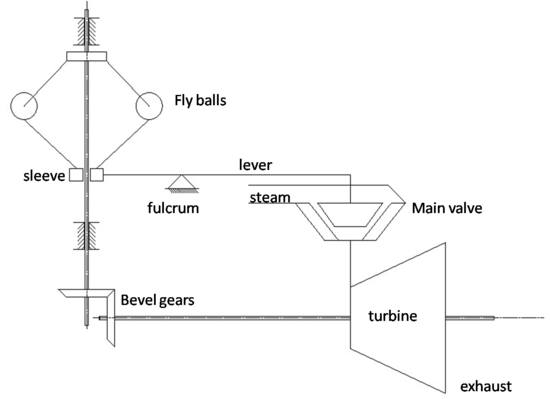

A governor is the component of the steam turbine control system that regulates the rotational speed in response to changing load conditions. The governor output signal manipulates the position of the steam inlet valve or nozzles which in turn regulates the steam flow to the turbine. The governing of the turbine is necessary as a turbine is directly coupled to an electric generator which is required to run at a constant speed under all fluctuating load conditions

In a steam turbine, there are three types of governors are used.

Throttle Governing of Steam Turbine

Nozzle Control Governing Of Steam Turbine

Bypass Governing of Steam Turbine.

Throttle Governing of steam turbine

In this governing system, the pressure of the steam turbine is reduced at the Turbine entry thereby decreasing the availability of energy. In this method, steam is pass through the restricted passage thereby reducing its pressure across the governing valve. The flow rate is control through a partially opened steam turbine control valve. Throttle governing is used for small turbines. Its cost is less and it has a simple mechanism. In throttle governing the steam is throttled whenever the load falls below the design load to maintain turbine speed constant. In this system, a centrifugal governor is driven from the main shaft of the turbine by belt or gear arrangement. A control valve is used to control the direction of oil flow.

Nozzle control governing steam turbine

Nozzle control governing of steam turbine is basically used for part-load condition. Some sets of nozzles are grouped together and each group of the nozzle is supplied steam controlled by valves.

Bypass governing of steam turbine

The bypass line is provided for passing the steam from the first stage nozzle box into a later stage where work output increases. This bypass steam is automatically regulated by the lift of the valve which is under the control of the speed of the governor for all loads within its range.