Cogeneration, or combined heat and power (CHP), is a highly efficient method of generating electricity and useful heat from a single fuel source. In South Africa, where energy demands are high and the need for sustainable solutions is paramount, implementing small steam turbines for Mini Cogen systems presents an excellent opportunity.

Benefits of Small Steam Turbines for Mini Cogen:

Energy Efficiency: Steam turbines maximize energy efficiency by utilizing waste heat from industrial processes or power generation to produce additional electricity, thereby reducing energy waste.

Reduced Emissions: Cogeneration systems with small steam turbines help lower greenhouse gas emissions by optimizing the use of primary fuel sources and reducing reliance on fossil fuels.

Cost Savings: By generating electricity and heat simultaneously, Mini Cogen systems can significantly reduce energy costs, making them an economically viable choice for various applications.

Power Reliability: Mini Cogen systems equipped with small steam turbines offer increased power reliability, ensuring a continuous energy supply for critical operations, such as hospitals, manufacturing plants, or commercial buildings.

Applications of Small Steam Turbines in South Africa:

Industrial Sector: Small steam turbines can be deployed in manufacturing facilities, chemical plants, and refineries to capture waste heat and generate electricity, thus enhancing overall energy efficiency and reducing operating costs.

Residential and Commercial Buildings: Mini Cogen systems powered by small steam turbines can supply electricity and heat to residential complexes, hotels, shopping malls, and office buildings, meeting their energy demands while reducing reliance on the grid.

Agriculture and Food Processing: South Africa’s agricultural sector can benefit from small steam turbines in mini Cogen systems. They can utilize agricultural waste or biomass as fuel to generate electricity and heat, supporting sustainable farming practices and reducing energy costs for food processing facilities.

Available Options for Small Steam Turbines in South Africa:

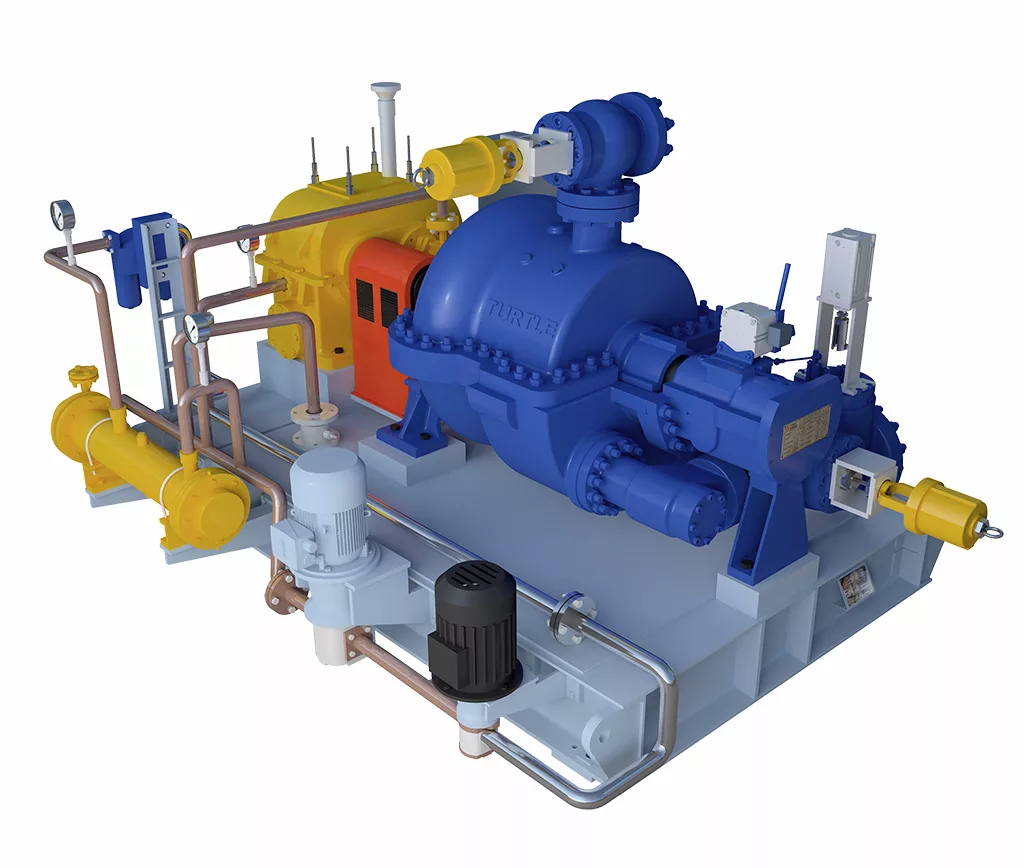

Steam Turbines: Companies such as Turtle Turbines offer compact Mini Cogen turbines suitable for small-scale cogeneration systems. These turbines are designed to handle lower steam flow rates and can generate electricity in the range of a few kilowatts to several megawatts.

Conclusion:

Implementing small steam turbines for Mini Cogen in South Africa presents an attractive solution to meet the country’s energy demands while promoting sustainability. The numerous benefits, including enhanced energy efficiency, reduced emissions, and cost savings, make them a viable choice across various sectors. With the availability of steam turbines and ORC turbines, South Africa has access to reliable options to deploy these systems effectively, supporting a greener and more resilient energy future.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com