Cogeneration or Combined Heat and Power (CHP) is the combined generation of heat and power. It is not a single technology, but an integrated energy system. Cogeneration first involves producing power from a specific fuel source, such as natural gas, biomass, coal, or oil. During fuel combustion, Cogeneration captures the excess heat which would have otherwise been wasted.

The captured heat can be used to boil water, create steam, heat buildings, etc. For instance, in the oil sands, steam is required to produce bitumen. By using Cogeneration, energy companies can simultaneously produce steam for production and electricity on site. By minimizing waste, Cogeneration plants generally convert 75-80% of the fuel source into usable energy, in comparison with conventional systems which only covert about 45%

When the heat captured is used to produce electricity, the process is referred to as Combined cycle.

Cogeneration has multiple economic and environmental benefits. By reducing the amount of fuel needed to generate electricity and heat, companies that use Cogeneration increase self-sufficiency, decrease costs and reduce greenhouse gas emissions and pollutants.

Globally, Cogeneration is becoming more widely adopted for meeting heat and electricity needs. Cogeneration technologies provide over 11% of electricity needs in Europe. China and India are expected to increase power production through Cogeneration by 28% before 2030. Cost-efficiency improvements and demand for climate change mitigation will increase the adoption of Cogeneration.

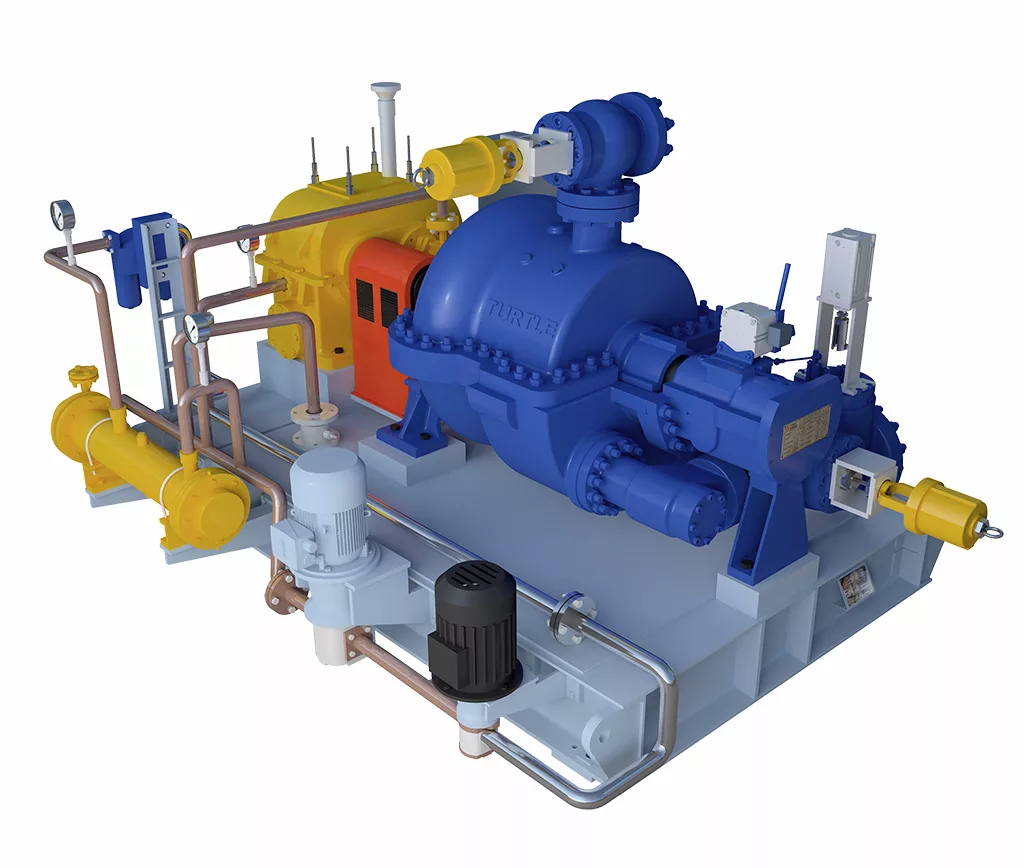

Turtle Turbines is the global Manufacturer of Steam Turbines in India. For more Information please visit on https://turtleturbines.com

Largest Top 5 Steam Turbine Manufacturers in the world

Steam turbines have played a Important role in the evolution of power generation, transforming the way we harness energy. These remarkable machines have powered industries, cities, and entire nations. Following are largest top 5 steam turbine manufacturers in the world. Who have helped shape the global energy landscape.

Siemens Energy

Siemens Energy is one of the largest top 5 steam turbine manufacturer in the world which is a global powerhouse when it comes to steam turbine manufacturing. With a legacy spanning over a century, Siemens has consistently delivered cutting-edge technology. Their largest steam turbines manufacturers in the world are known for their efficiency, reliability, and innovative design. Siemens has been a driving force behind the transition towards sustainable energy solutions, making them a key player in the industry.

- General Electric (GE)

General Electric, often referred to as GE, is another largest top 5 steam turbine manufacturer in the world of steam turbines. Their turbines are a common sight in power plants across the globe. GE has a history of innovation and adaptation, offering a wide range of turbines that cater to various industries, from aviation to energy generation. Their commitment to research and development keeps them at the forefront of the industry in the largest top 5 steam turbine manufacturer in the world. - Mitsubishi Heavy Industries (MHI)

Mitsubishi Heavy Industries, a Japanese conglomerate, has earned its spot among in the largest top 5 steam turbine manufacturers in the world. MHI’s turbines are renowned for their durability and performance. They have a strong presence in the energy sector, with a focus on enhancing the efficiency of power generation. MHI’s dedication to quality has made them a trusted name in the field of largest top 5 steam turbine manufacturer in the world. - Ansaldo Energia

Ansaldo Energia, an Italian company, has made significant contributions to the largest top 5 steam turbine manufacturer in the world in industry. Their turbines are recognized for their flexibility and adaptability, making them suitable for various applications. Ansaldo Energia has also embraced green technologies, aligning with the global shift towards sustainable energy production. - Dongfang Electric Corporation

Hailing from China, the Dongfang Electric Corporation has rapidly risen to prominence in the steam turbine manufacturing sector. They are known for their state-of-the-art technology and cost-effective solutions. As largest top 5 steam turbine manufacturer in the world, China’s energy demands continue to grow, Dongfang Electric has played a vital role in meeting the nation’s power needs.

Conclusion

Steam turbines have a storied history and remain an integral part of the energy landscape today. The top five steam turbine manufacturers mentioned here continue to innovate, meeting the ever-growing demands these companies will undoubtedly play a crucial role in shaping the future of global energy production. Their commitment to sustainability.

Turtle Turbines is a one of the most reputed steam turbine manufacturers in India for power generation, suitable for operation on the saturated and superheated steam boilers operating in the various industries. Based in India, the company has focus on providing sustainable solutions for power generation and energy efficiency.

Turtle Turbines salutes these top 5 steam turbines manufacturers in the world for their immense contribution. Turtle Turbines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications. For more information please visit on www.turtleturbines.com

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com

Low Pressure Steam Turbines

Low-pressure steam turbines are a crucial but often overlooked component in steam-based power generation and various industrial processes. Unlike their high-pressure counterparts, low-pressure steam turbines are designed to harness the residual energy in steam at the end of its cycle. These turbines are instrumental in maximizing efficiency and sustainability across a range of applications.

One of the key benefits of low-pressure steam turbines is their ability to capture energy that might otherwise be wasted. In many industrial settings and power plants, steam initially enters the system at high pressure, but as it moves through turbines and performs work, its pressure decreases. Low-pressure steam turbines step in to extract energy from this low-pressure steam, efficiently utilizing what would otherwise be considered “waste” steam. This not only improves overall system efficiency but also contributes to sustainability by reducing energy losses and associated costs.

Low-pressure steam turbines are particularly valuable in industries with continuous sources of low pressure steam, such as pulp and paper mills, sugar refineries, or petrochemical plants. By incorporating these turbines into the steam cycle, excess low pressure steam can be put to good use, driving auxiliary equipment or additional power generation. This reduces the need for external energy sources and, in turn, lowers greenhouse gas emissions, aligning with sustainability objectives.

In conclusion, low pressure steam turbines may not always steal the spotlight, but they are essential for achieving energy efficiency and sustainability. By efficiently utilizing low pressure steam in various industrial processes and power generation, these turbines help minimize waste and reduce the environmental impact of energy production. They are a practical and sustainable solution, demonstrating how even seemingly minor components of complex systems can play a vital role in our journey toward a greener and more sustainable future. Turtle Turbines focus on refining turbine designs, optimising steam parameters, and utilizing innovative materials to maximize energy conversion while minimising energy losses.

|

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com

Best Practices for Steam Turbine Manufacturers

In the field of energy production and industrial processes applying Cogeneration plants, steam turbines play a pivotal role. These sophisticated machines are essential for converting thermal energy into mechanical energy, powering various applications, from electricity generation to propulsion systems in ships. Steam turbine manufacturers, therefore, hold a significant responsibility in ensuring the efficiency, reliability, and safety of these critical devices.

1. Precision Engineering and Quality Control

One of the fundamental pillars of steam turbine manufacturing is precision engineering. Steam Turbine Manufacturers employ cutting-edge technology and adhere to strict quality control processes to create turbines that operate at optimal efficiency. This includes precision machining of components, stringent material selection as per guidance provided by API 611, NEMA etc., and rigorous testing protocols. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems aid in creating turbine components with tight tolerances, minimizing energy losses due to friction and ensuring a longer operational lifespan.

2. Thorough Design and Simulation

Before any physical manufacturing begins, Steam Turbine Manufacturers invest heavily in designing and simulating the turbine’s performance. Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) are employed to model the flow of steam and stress analysis in different components. These simulations help engineers optimize the turbine’s design for maximum efficiency and durability. They also aid in predicting potential weak points and stress concentrations, enabling manufacturers to make necessary improvements before production begins. Tools such as D & P FMEA enable eliminating any failures in Manufacturing, Production and Operation of these critical equipments.

3. Robust Material Selection

The selection of materials for steam turbine components is critical. Steam Turbines Manufacturers opt for materials that can withstand high temperatures and pressures, resist corrosion, and provide excellent mechanical properties. Stainless steel and nickel-based alloys are often favored due to their superior performance in these harsh operating conditions such as saturated steam conditions. Moreover, Steam Turbine Manufacturers ensure the use of materials that meet industry standards and adhere to strict metallurgical specifications to prevent premature wear and failure.

4. Periodic Maintenance and Health Monitoring

The responsibility of Steam Turbine Manufacturers doesn’t end with the delivery of their products. They often provide Maintenance and Health Monitoring services to ensure the turbines continue to operate efficiently throughout their lifecycle. This includes regular inspections, performance evaluations, and predictive maintenance based on data collected from sensors and monitoring systems. These practices help identify potential issues before they become critical, minimizing downtime and maximizing the lifespan of the turbines.

In conclusion, Steam Turbine Manufacturers face a complex and demanding field that requires a commitment to precision, innovation, and quality. By adhering to best practices such as precision engineering, thorough design and simulation, robust material selection, and ongoing maintenance and monitoring, steam turbine manufacturers play a crucial role in providing efficient and reliable energy solutions for various industries. Their dedication to these practices ensures that steam turbines continue to be at the forefront of energy generation and industrial processes.

Turtle Turbines is a one of the most reputed steam turbine manufacturer in India for power generation, suitable for operation on the Superheated and Saturated steam boilers operating in various industries. Based in India, Turtle Turbines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications manufactured to Global Standards and backed up by Remote Performance Monitoring Systems for Health and Performance Monitoring. Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com

Steam Turbine Manufacturing

Steam turbine is the machine which extracts thermal energy from the steam and converts it to mechanical work on a rotating output shaft and then into electric energy with the help of alternator. The world of steam turbine manufacturing, uncovering the precision, innovation, and craftsmanship that make them an indispensable part of our modern lives.

The Manufacturing Process:

The range of potential processes and tools that can be applied to manufacture the steam turbine. Following are the processes which used for the steam turbine manufacturing. Design and Engineering: In steam turbines manufacturing engineers use advanced software and simulation tools to model the turbine’s performance and efficiency.

Factors such as rotor design, blade shapes, and material selection are critical to optimizing the turbine’s performance.

Precision Machining: Steam Turbine Manufacturing demands precision machining. Large rotors and blades, often made of high-strength materials like stainless steel or titanium, require specialized equipment and skilled craftsmen.

CNC machines ensure the highest level of accuracy, shaping components to tolerances measured in microns.

Quality Control: Quality control is paramount in steam turbine manufacturing. Every component undergoes in testing to ensure it meets strict quality standards.

Non-destructive testing techniques like ultrasonic and magnetic particle inspections detect even microscopic defects.

Assembly:

In steam turbine manufacturing, assembling is a complex process. Components, sometimes weighing several tons, are assembled with precision to create the rotor and casing.

The assembly process includes meticulous alignment and balancing to ensure the turbine operates smoothly.

Testing and Calibration: In steam turbine manufacturing,

prior to installation, each steam turbine undergoes extensive testing and calibration. This includes running the turbine at varying loads and speeds to verify its performance.

Testing ensures that the turbine can withstand the extreme conditions it will encounter in the field.

Innovations in Steam Turbine Manufacturing: Advanced Materials: In steam turbine manufacturing,

the use of advanced materials like nickel-based superalloys and composite materials allows for higher efficiency and durability.

These materials can withstand extreme temperatures and pressures, enhancing the turbine’s performance.

Digitalization: Digital technologies play a crucial role in modern steam turbine manufacturing. Computer-aided design (CAD) and simulation software optimize designs, while sensors and data analytics enable real-time monitoring and predictive maintenance.

Environmental Considerations: In Steam turbine manufacturing, manufacturers increasingly focused on sustainability. Efforts are made to reduce energy consumption during manufacturing and to design turbines that operate efficiently and emit fewer greenhouse gases.Turtle Turbines manufacturers the steam turbines from the range of 50kW to 3000kW. Turtle Turbines supplies steam turbine in the world.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com

How Steam Turbines transform Heat into Power:

In the realm of energy conversion, the steam turbine, machines that transform heat to power, reigns as a mechanical marvel that has reshaped the way we generate power. At its core, a turbine is a device that captures the kinetic energy of a moving fluid and translates it into useful work. In the context of steam turbines, this fluid is steam, and its potential for revolutionizing industries is boundless.

The intricate process of a steam turbine transforming heat to power begins with the controlled heating of water, creating high-pressure steam in a boiler. This steam passes through the turbine’s precision-engineered blades, causing the rotor to spin rapidly. The kinetic energy thus generated propels a generator connected to the same shaft, producing electrical power. Thus the steam turbines transform heat to power. The beauty of the steam turbine lies in its efficiency and adaptability. It can be scaled up for power plants or down for propulsion systems in ships, each time transforming heat into power.

Steam turbine play an integral role in power generation, serving as the beating heart of various energy plants. From coal-fired to nuclear power stations, the Kinetic energy of turbines are converting the stored thermal energy of fuels into electrical power that lights up homes and industries. Moreover, with the surge in renewable energy, steam turbines find new purpose in harnessing solar or geothermal heat to produce clean electricity. This adaptability showcases the turbine’s significance in steering us toward a sustainable energy future and thus steam turbines transform heat into power.

In conclusion, the steam turbine stands as a testament to human engineering prowess, transforming heat into power that drives our modern world. Its ingenuity lies in its ability to harness the latent power of steam, translating it into kinetic energy that fuels industries and powers our lives. Turtle Turbines continue to explore cleaner and more efficient energy sources, the steam turbine’s legacy evolves, reminding us that the journey from heat to power is a transformative one.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com

Enhancing Sustainability in the Food Processing Industry through Cogeneration and Steam Turbines

In today’s fast-paced world, the food processing industry plays a pivotal role in delivering the products we consume daily. However, this industry is not only about creating delicious treats; it also has significant energy demands. One way this sector is striving towards sustainable operations is by harnessing the power of Cogeneration and Steam Turbines. These technologies not only address energy needs but also contribute to environmental conservation.

Cogeneration and Steam Turbines have emerged as a game-changer in the energy-intensive food processing industry. They work on a simple principle: converting the energy contained within steam into process demands, which can then be used to generate electricity as well. By utilizing steam turbines, the industry can tap into the energy-rich byproducts of its processes, significantly reducing its reliance on fossil fuels. This is where the concept of cogeneration comes into play.

Cogeneration, also known as combined heat and power (CHP), involves the simultaneous production of electricity and useful heat from a single energy source. In the context of the food processing industry, this means that the steam generated by the Medium or High Pressure Boiler can be channeled through a steam turbine to produce electricity, while the residual heat can be harnessed for various heating processes within the facility. Cogeneration and Steam Turbines not only enhance the energy efficiency but also reduces greenhouse gas emissions, making cogeneration a win-win for both the industry and the environment.

One of the key applications of Cogeneration and Steam Turbines in the food processing sector is the back pressure steam turbine system. This system involves allowing the steam to expand and perform work in the turbine before being used for heating or other processes. The exhaust steam from the turbine is then utilized for different applications within the facility, such as cooking, sterilization, or drying. By optimizing this process, the industry can maximize the benefits of both electricity and heat generation, effectively reducing energy costs and minimizing waste.

In conclusion, as the food processing industry continues to expand, so do its energy requirements. Embracing sustainable practices is no longer an option but a necessity. Cogeneration and Steam Turbines, particularly through the implementation of back pressure steam turbine systems, offer an innovative solution to the sector’s energy challenges. By efficiently converting steam into electricity and heat, the industry can not only become more self-sufficient but also significantly decrease its carbon footprint. As technology advances and the importance of environmental consciousness grows, integrating these technologies could pave the way for a greener and more efficient future for the food processing industry.

Turtle Turbines is a one of the most reputed steam turbine manufacturer manufacturer in India for power generation, suitable for operation on the Satudated steam boilers operating in the food processing industry. Based in India, the company has a focus on providing sustainable solutions for power generation and energy efficiency. Turtle Tubrines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications. For more information please visit https://turtleturbines.com

The Role of Low Pressure Steam Turbines and Cogeneration

In an era where sustainable practices are gaining paramount importance, industries are actively seeking innovative ways to cut down on energy consumption and minimize their carbon footprint. One such solution gaining traction is the implementation of Low Pressure Steam Turbines and Cogeneration in Industrial Processes. This not only brings about significant energy savings but also can reshape the industrial landscape.

Low Pressure Steam Turbines and Cogeneration have emerged as a key solutions in the field of energy conservation. These turbines are designed to harness the energy from low pressure steam, a prominant energy source available in various industrial processes. By capturing this energy and converting it into mechanical power, Low Pressure Steam Turbines and Cogeneration create a valuable source of electricity that can be utilized on-site to reduce the power demad bill from the utility grid. This innovation not only reduces waste of potential energy but also presents a cost-effective solution for industries aiming to optimize their energy usage.

Coupling Low Pressure Steam Turbines with Cogeneration further amplifies the advantages. Cogeneration, also known as combined heat and power (CHP), is a strategy where a single energy source generates both electricity and useful heat required or the process. In this context, Low Pressure Steam Turbines and Cogeneration prove to be invaluable as they efficiently convert steam energy into power while the residual heat can be used for various heating processes within the facility. This symbiotic relationship between power and heat generation ensures that no energy potential goes to waste, ultimately resulting in a substantial reduction in energy costs.

A prominent equipment in the Low Pressure Steam Turbines and Cogeneration arena is the back pressure steam turbine. This technology operates by allowing steam to expand and perform work in the turbine before being utilized for heating or other industrial applications. The key advantage lies in its versatility – the exhaust steam from the back pressure steam turbine can be employed for multiple processes, ranging from drying to distillation. This adaptability not only enhances energy efficiency but also presents industries with a flexible approach to energy management, catering to their specific needs and requirements.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on the Low Pressure Saturated to High Pressure Superheated Steam Boilers operating in the process industry. Based in India, the company has a focus on providing sustainable solutions for power generation and energy efficiency. Turtle Tubrines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications. Turtle Turbines is one of the most reputed Steam Turbine Manufacturer in India. To know more about the prodcuts visit now https://turtleturbines.com

Maximizing Efficiency: Unveiling the Wonders of Extraction Back Pressure Steam Turbines

Extraction Back Pressure Steam Turbines play a crucial role in harnessing the power of steam to generate electricity and provide thermal energy across various industries. Extraction back pressure steam turbines are a specific type of steam turbine that efficiently utilizes both mechanical and thermal energy from high-pressure steam. Extraction back pressure steam turbines have the ability to extract intermediate-pressure steam at various stages of the turbine’s expansion process.

This extracted steam can then be utilized for industrial processes or district heating, enhancing the overall efficiency of the power generation system. The primary principle behind the extraction back-pressure steam turbines lies in the controlled extraction of steam at different pressure levels. This extracted steam, instead of being completely expanded in the turbine, is diverted for specific applications.

Extraction Back pressure steam turbines are used to enhance efficiency by utilizing the extracted steam for other processes like heating or industrial work, these turbines maximize the energy extracted from the steam, improving overall efficiency. The extraction steam pressure can be customized to various pressure and temperature levels, making it adaptable to a wide range of industrial processes, such as cogeneration and district heating. Extraction-back pressure steam turbines contribute to cost savings by reducing the need for separate energy sources for different applications, making them an economical solution for power and heat generation. Extraction back pressure steam turbines are environmentally friendly, a step towards sustainable energy generation. Using excess steam for productive purposes minimizes wastage and carbon emissions.

Turtle Turbines is the global Manufacturer of Steam Turbines in India. For more Information please visit on https://turtleturbines.com

Steam Turbine Rotating Machinery

The Steam turbine stands as a testament to human brilliance. This remarkable creation, entwining the principles of thermodynamics and mechanical precision, has redefined the landscape of power generation and industrial applications. Central to its functionality is the concept of rotating machinery, a symphony of components working in harmony to convert steam’s latent energy into tangible power.

At the heart of every steam turbine lies an intricate web of rotating machinery. This ensemble typically comprises a shaft mounted with rotor wheels and blades carefully positioned to capture the force of pressurized steam. As steam is directed at these blades, their unique shape and alignment propel the shaft into a spinning motion. The mechanical energy thus generated serves as the driving force for electricity generation or other mechanical tasks, exemplifying the elegant marriage of science and engineering.

The applications of steam turbines with their intricate rotating machinery span far and wide. Power generating plants, fuelled by coal plants, gas plants, or nuclear reactions, rely on these turbines to generate electricity efficiently. In high domains, steam turbines propel ships across oceans, embodying reliability and power in a compact form. Industries leverage these turbines for processes ranging from oil refining to chemical production, marking them as catalysts for progress. Looking ahead, the ongoing synergy between rotating machinery and technological advancements promises an even more efficient, sustainable, and versatile future for steam turbines.

The captivating tale of steam turbines intertwined with rotating machinery underscores human innovation’s prowess. These mechanical marvels encapsulate the essence of converting heat to power, fuelling the machinery of modern civilization. As Turtle Turbine continue refining the technology of energy conversion and mechanics, steam turbines remain beacons of how science and engineering can shape a world brimming with potential. Turtle Turbines is a Global Manufacturer of Steam Turbines. For more information visit now https://turtleturbines.com

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com