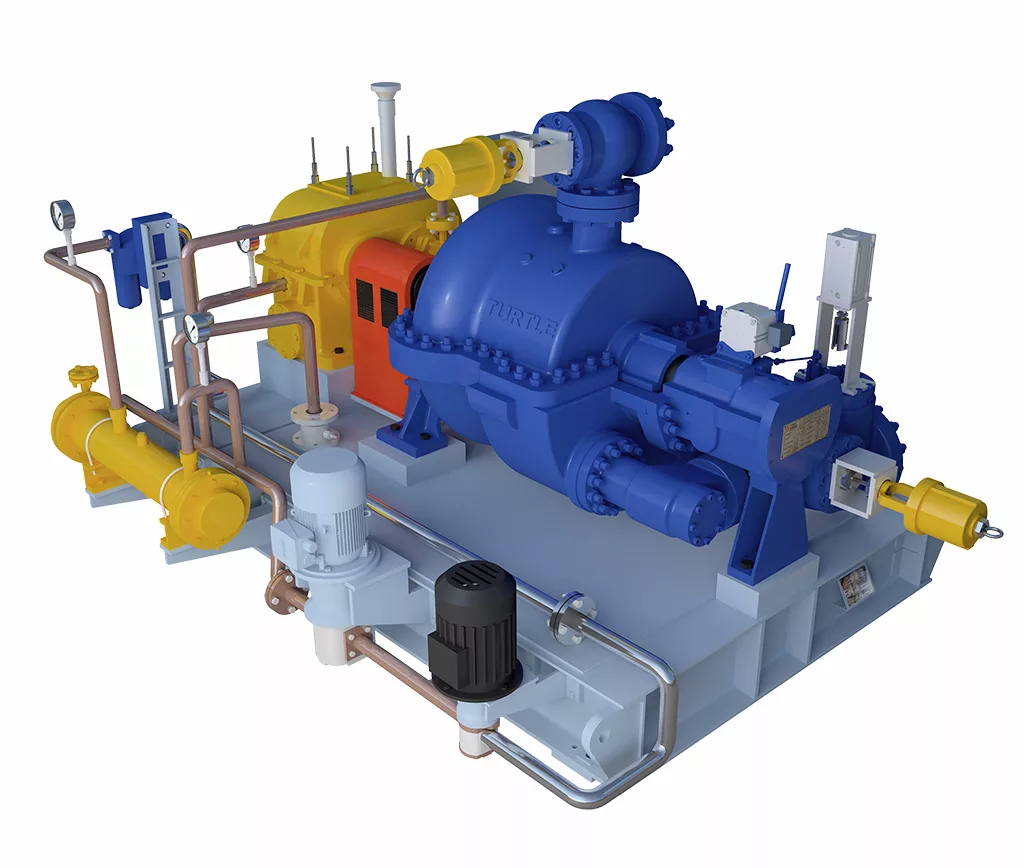

A remarkable example of power generation is Steam Turbine Energy Conversion by effectively transferring the latent energy captured within steam into tangible mechanical power. These time tested devices assume an important role across industries, driving processes and propelling the machinery that powers modern civilisation expressing the very essence of energy conversion at its finest.

Steam Turbine Energy Conversion, the operation of a steam turbine realize the fundamental principle of energy conversion. Steam, generated by heating water through various methods, enters the turbine at raised pressures and temperatures. As it courses over the turbine blades, the energy within the steam is transferred, inducing a dynamic spin of the turbine blades. This rotational motion is harnessed to drive generators, where mechanical energy undergoes a transformative process, culminating in the generation of electrical energy—an effective display of energy conversion in action.

Steam turbine efficiency stands as the cornerstone of effective Steam Turbine Energy Conversion. Turtle Turbines continuously refines turbine designs, optimize steam parameters, and integrate cutting-edge materials to ensure the maximization of thermal energy conversion into mechanical work.

Turtle Turbines’ enhanced steam turbine efficiency not only augments power output but also lends a hand in environmental preservation, curbing fuel consumption and reducing emissions, thus cementing the status of steam turbines as indomitable agents of energy conversion.

In an era marked by surging energy demands and sustainability concerns, the prowess of Steam Turbines Energy Conversion remains unparalleled. As Turtle Turbines pivots towards cleaner energy sources, steam turbines continue to spearhead energy conversion technology, promising an energy-efficient and environmentally conscious future for generations to come.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com