The term Energy conservation itself defines the energy which can be conserved by reducing wastage and losses, improving efficiency through technological upgrades, and improving operations and maintenance.

FACT I: Many industrial facilities produce steam at a pressure higher than that demanded by process requirements. Steam passes through pressure-reducing valves at various locations in the steam distribution system to reduce its pressure. A Back-Pressure Steam Turbine can perform the same pressure-reducing function as a PRV while converting steam energy into electrical energy, which leads down to Energy Conservation. A pressure difference must exist between the steam supply and the exhaust for any Steam Turbine to operate.

FACT II: Considering waste heat from Industries, which can recover heat from a hot gas or water stream and produces steam that can be used in industrial and manufacturing processes or can be also used to drive a Steam Turbine to improve efficiency, reduces operating cost and lowering carbon footprints. This leads us to Energy Conservation. Waste Heat is basically the byproduct from Chemical Industries, Gas Turbines, etc., where this waste heat can be converted into steam, which can be used further in Steam Turbine Generators to produce Electrical Power. Ultimately this fact will increase the value of Energy Conservation.

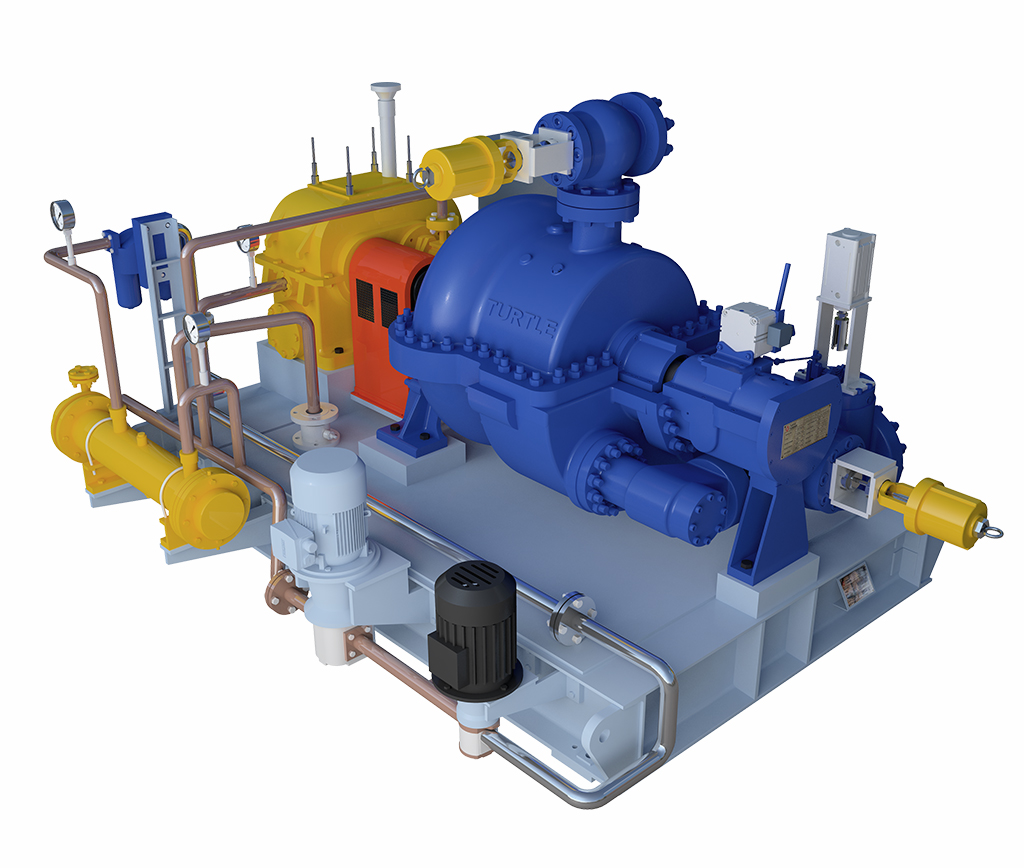

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.