Knowing the true cost of power is very important to improving the company’s bottom and operation efficiency.

The power we use has both economic and social impacts and to understand the true cost of power we need to dig deep into both of them.

Cost of power generation:

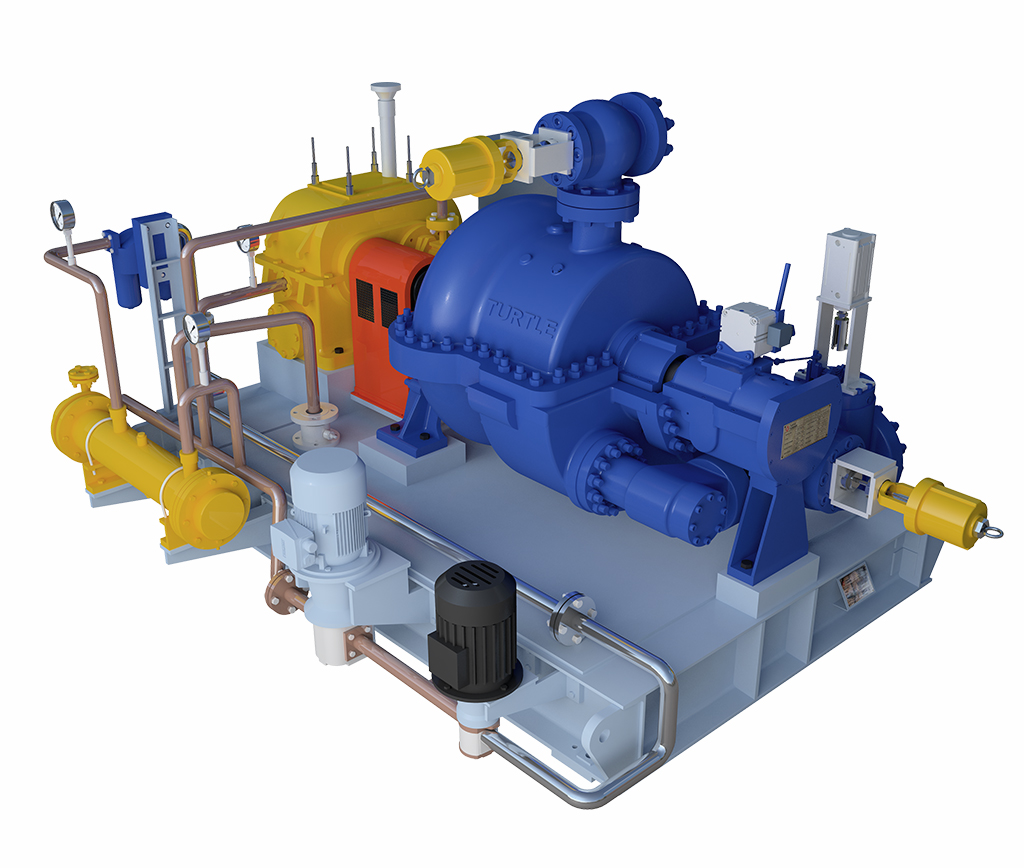

There are many ways to generate power, mainly hydropower, nuclear power, solar wind, and thermal power plants. Out of these main categories, thermal power plants are the most popular and have the highest market share among the others. Most thermal power plants work on the Rankine cycle. The fuel such as coal and natural gas is burned into the boiler. The boiler generates high pressure and superheated steam. Steam is further passed through a steam turbine to generate the power. Owing to the intrinsic limited efficiency of the Rankine Cycle, only about 30% of Energy generated by burning the fuel is converted into Electrical Power.

per kW of power generated majorly depends on

Fixed costs (FC), mainly interest, depreciation, insurance, and taxes, depending on the capital invested, i.e. on the construction costs of the plant including the cost of the land.

Operation and maintenance (O & M) cost cover salaries and wages, overhauling of equipment, repairs including spare parts, water, lubricating oil, chemicals, and miscellaneous expenses.

Fuel costs, depend on the amount of electricity generated. Cost also varies with the quantity of fuel, source of fuel, and availability of fuel. Apart from capital expenditure on the infrastructure and capital equipment the consumption of fuel accounts for more than 50% of the power plant operating cost.

Cost of distribution:

Usually, Power is generated at a centralized location and transmitted via Grid to the industry. Power distribution requires a huge network of wire/cable of several hundred kilometers along with many distribution stations. developing this infrastructure is very capital intensive. Up to 20% of this power (ie. 6% of the Energy in Coal) is lost as Transmission and Distribution losses, thus only about 24% of Energy reaches the consumption point. The remaining 76% is dumped as Heat into the atmosphere adding to Global Warming.

As an industrialist, we can reduce the cost of power by generating our own power at the site ( near to the point of consumption) which almost eliminates the capital infrastructure cost of the power distribution network and also minimizes the distribution losses. In case of Cogeneration, both Heat and Power are generated from a single primary source of Fuel. The exhaust heat from the Cogeneration Power Plant can be utilized in the process of heating the industry and the Power is consumed locally. The system efficiency of the Cogeneration Power Plant thus reaches as high as 84%, compared to just 24% of Centralised Power Plant.

Generating power at the site through waste heat or instead of the PRS system is the best option to reduce the cost of power and increase the process efficiency.

On-site power generation reduces the waste heat dumped into the atmosphere. Which in turn reduces the global warming effect by almost 70% as compared to the conventional centralized power generation.