An effective way to increase energy efficiency is to recover waste heat. The process industry mainly consumes two types of energy. Fossil fuel to generate process heat and electric energy to drive motors and for use in specific process steps. Waste heat can also be used to generate steam, which can be used to drive mechanical processes or generate electricity. Hence cogeneration facilities are designed to use one energy resource to create both heat and electricity. Steam Turbines play a very important role in waste heat recovery applications. Steam Turbines are very essential to generate the power in waste heat recovery process because it generates power within 25% of the cost of the grid / utility power cost.

In the waste heat recovery process, the energy and cost-saving potential are closely linked to the flow of heat in the plant in most cases. Waste heat recovery is basically used to try to recover maximum amounts of heat in the plant and reuse it as much as possible, instead of just releasing it into the atmosphere. Waste heat recovery steam generators can be used to generate steam for district heating or factory processes or to drive a steam turbine to generate more electricity.

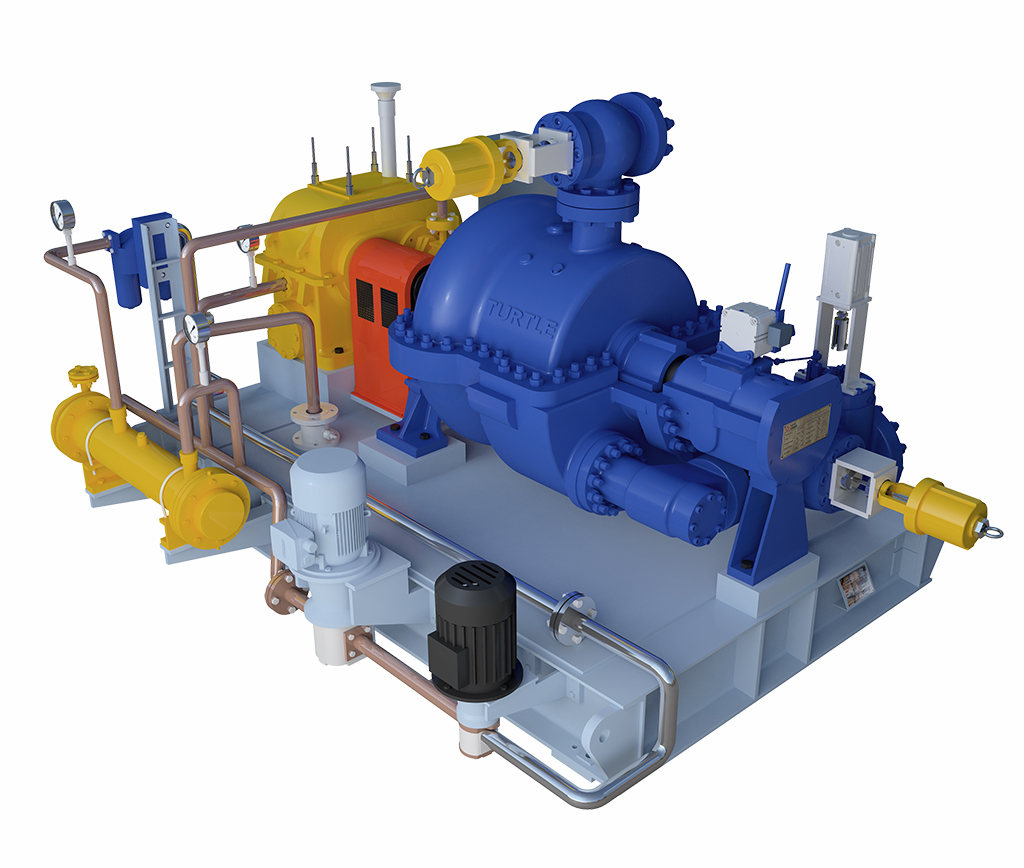

Turtle Turbines supplies steam turbines for Waste Heat Recovery also. For more information please visit turtleturbines.com

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.