An Energy Audit is a systematic examination and analysis of energy usage within a specific environment, such as a building, facility, or industrial process. The primary goal is to identify opportunities for improving energy efficiency, reducing energy consumption, and optimizing energy performance.

Based on the extent of energy audit conducted the results and outcomes of the Energy Audits will vary. Based on the extent of Energy Audit to be conducted, there are 3 Types of Energy Energy Audits.

1. Walk Through Energy Audits

Sometimes the Energy Audits need to be conducted only in preparation for a detailed audit. A Walk Through Energy Audit is a systematic inspection of an industry’s energy usage, aiming to identify areas where energy efficiency can be improved. This non-invasive audit is an excellent starting point for individuals or organizations looking to reduce energy costs and environmental impact.

Walk Through Energy Audits are conducted by an Experienced Energy Auditor and his / her Team. Usually, the Operations and Maintenance Team of the Industry becomes a part of the Walk Through Energy Audit. The team goes through the entire production facility and identifies various major and minor potential opportunities for improving energy efficiency, reducing energy consumption, and optimizing energy performance.

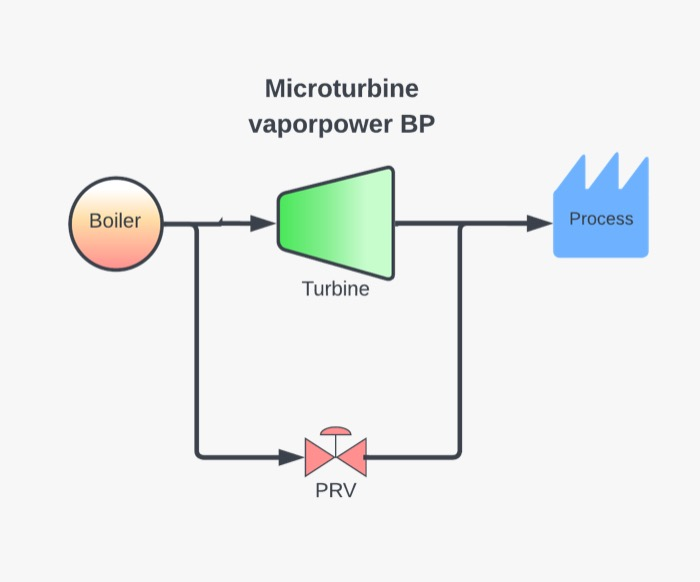

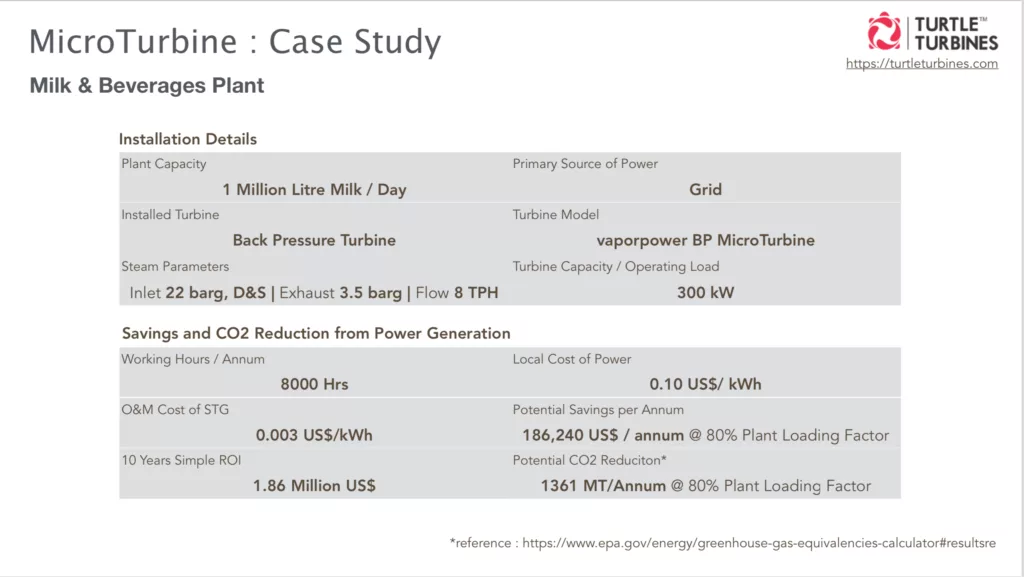

One of the easiest and most feasible Energy Saving Opportunities identified during Walk Through Energy Audits of process industries using steam are Pressure Reducing Valves (PRVs) also called as Pressure Reducing and De-superheating Stations (PRDS). Microturbines can be effectively used to work as PRVs to reduce the steam pressure and generate clean Electrical Energy using the pressure drop. vaporpower is one such popular and time-tested Microturbine used in various process industries.

2. Target Energy Audits

The outcome of a Walk Through Energy Audit can used to identify targeted areas to conduct Energy Audits. Walk Through Energy Audits done effectively with complete involvement of the Operations and Maintenance Teams of the Industry can lead to Target Energy Audits. The Operations and Maintenance Teams of the industries usually are generally aware of the ares where the most energy is being consumed as well as those areas where most energy is being wasted.

Target Energy Audits can prove to be very cost-effective since these are done with clearly identified areas. Such Audits can be quick and highly effective as compared to Detailed Energy Audits. The implantation of the outcomes of such audits can also be done very quickly.

If any Pressure Reducing Valves (PRVs) are identified as a possible Target for Energy Audit, Turtle Turbines can be approached with available steam data for a Free Analysis of Potential Power Generation. Data Form provided at the link may be used to provide the requested information for Free Evaluation of Power Generation Potential.

These Microturbines are designed for retrofit applications with plug-and-play design.

3. Detailed Energy Audits

Detailed Energy Audits are also called Diagnostic Energy audits and are usually very comprehensive in nature. Detailed Energy Audits are conducted to scan across the entire Industrial setup and generate sufficient data for desk analysis. Detailed Energy Audits are expected to provide more in-depth analysis leading to the identification of potential energy conservation opportunities. Detailed Energy Audits are conducted by Professional Energy Auditors who are qualified to carry out such assignments. these are not only limited to identifying the possible energy conservation potential at various consumption points in the Industrial setup but also provide in-depth understanding in terms of Internal Rate of Return (IRR), Net Present Value (NPV) and Life Cycle Cost (LCC)

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com