Steam Turbine is the most valuable and essential equipment in sugar, distillery, food industry, Edible oils, Paper Industry, Dairy plants, Cement plants and many more industries. Because it’s a power generating equipment and its better to operate than other power generating equipment. It can generate power within lowest cost as compared to other sources.

However, pressure on the energy industry increases. As prices increases and the focus on sustainable grows, industry owners/players are starting to find leverage solutions. And also strategies that would help them to reduce their steam turbine outage costs. And increase steam turbine life cycle.

Following are the some valuable strategies that can help you to reduce your steam turbine outage costs.

- Keep control systems failure free and maintained.

A good control system can increases reliability, reduce maintenance and improve diagnostics and employ more precise control on steam turbines. - Keep spares in stocks.

Keep Consumable spares and essential required spares in stock so that it can save the time and also power cost in the period of failure of this spares, turbine will run within short time after replacement. Maintain Consumable and critical spares on periodically basis. - Take spares from OEM only.

The spares taken from OEM are genuine, quality spares which enhances the operational reliability of the steam turbine as they are manufactured to quality standards. Because the quality and inspection processes applicable to spares are same as that of turbine manufacturing process to ensure consistently high quality. - Do preventive maintenance –

It is the predetermined periodic based maintenance activity. In that, Steam turbine is taken offline, opened up and inspected. After visual inspection repairs are made and machine will put back online. In this type of maintenance replacement, overhauling and remanufacturing activities is done at fixed periodic intervals regardless of machine condition at the time. - Do sceduled maintenance.

In scheduled maintenance steam turbine bearings and Seals should be physically inspected every quarter or years. This entails opening the bearing housings, removing and inspecting the bearings and Seals and replacing any components as needed. Scheduled maintenance generally done during a planned shutdown.

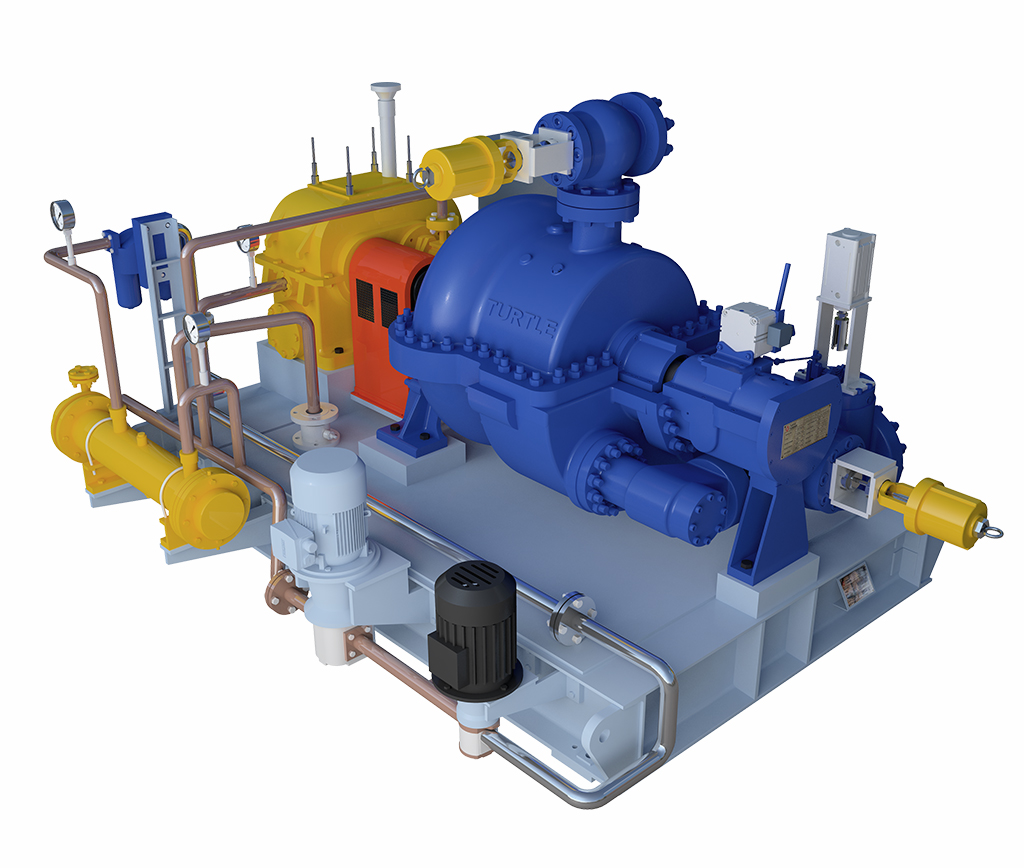

Turtle Turbine Manufactures the steam turbines ranges from 50kW to 3000kW and also provides spares of high quality standards. For more information please visit on www.turtleturbines.com.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.