The steam turbines which work on saturated steam at the inlet of the turbine instead of superheated steam are known as saturated steam turbines. It does not require any additional superheater in a boiler to achieve a specified degree of superheat.

Many industrial processes prefer to use saturated steam over superheated steam. This is because saturated steam has properties that give saturated steam advantages over a superheated steam

- Uniform heating throughout the heat transfer process

- Ability to maintain temperature by maintaining pressure.

- A high heat transfer coefficient.

In particular, this high heat transfer coefficient makes saturated steam an obvious choice over superheated steam for many industrial applications. Mostly known as utility steam

Utility steam makes up the majority of the steam consumed by the industry. Saturated steam is utilized for drying the products, humidification of the environment or products, automizing the fuel, sterilizing the equipment, cleaning the material, moisturizing and process heating, and many more applications.

Thus the availability of saturated steam is almost in every industry from pharma, chemicals Distillery to food. Every industry uses saturated steam for its process applications.

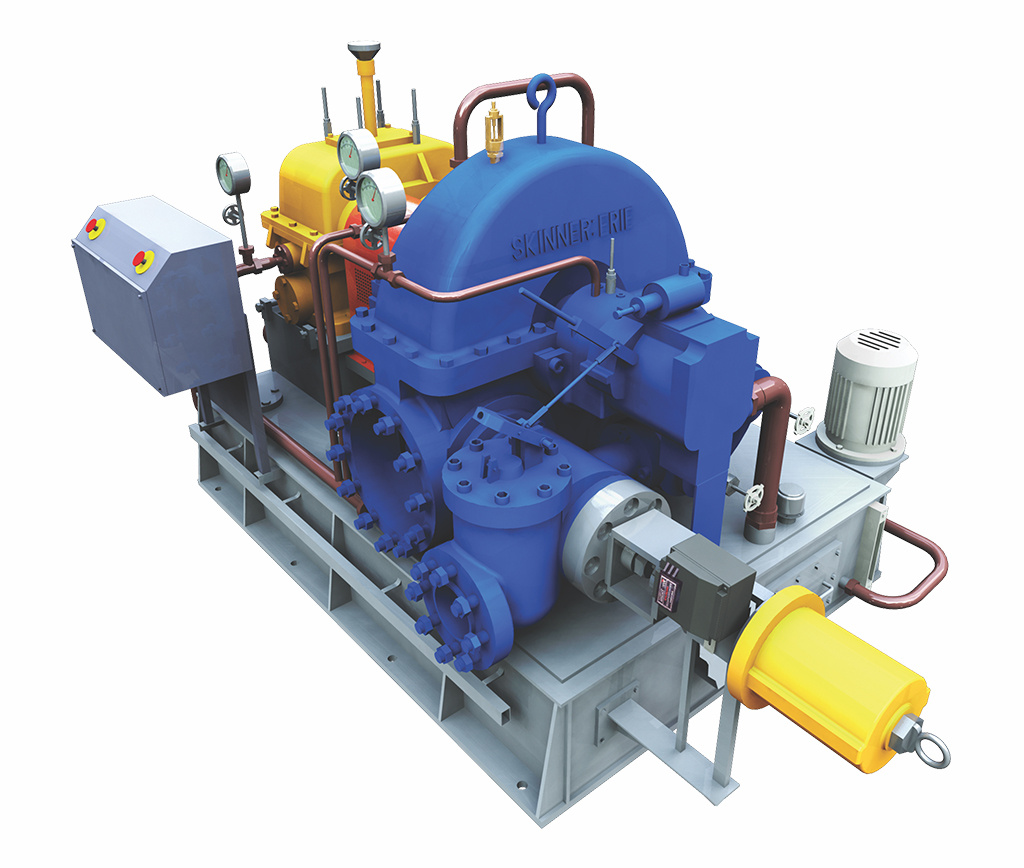

Turtle turbines have the expertise and vast experience in using this Saturated steam to generate power. Most industrial boilers / so-called packaged boilers generate steam at around 10 kg/cm2 wrt to IBR norms this steam is then reduced to a process pressure of about 3 kg /cm2 to 4 kg/cm2 through the PRS system. The saturated steam turbines developed by Turtle turbines can be used as a replacement for the PRS/ PRDS to reduce the pressure from boiler pressure to process pressure. And it uses the pressure and heat which is lost in PRS to generate power. The power generation through saturated steam has many challenges the main challenge is the water content in steam at the exit of the turbine. The water droplets at such high velocities of turbine exit lead to severe damage to turbine blades. Turtle turbines have designed turbine which avoids this threat by efficiently expanding the steam at every stage and maintaining the desired steam quality at the exit of the turbine while generating maximum possible power.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.