The black carbon industry is a very energy-intensive industry.

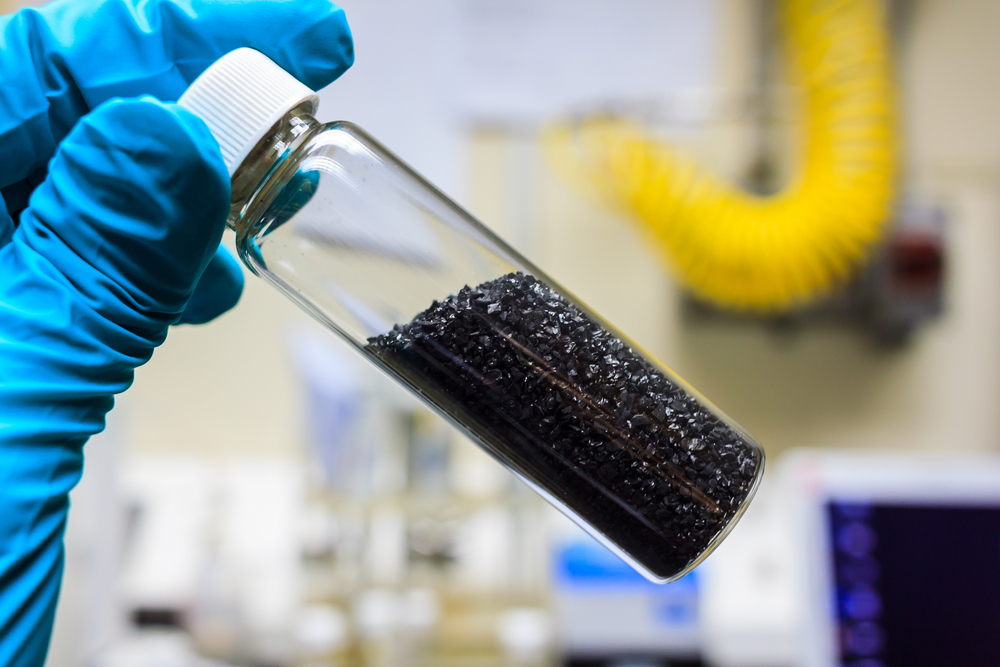

Carbon black is produced with the thermal decomposition method or the partial combustion method using hydrocarbons such as oil or natural gas as raw material.

The characteristics of carbon black vary depending on the manufacturing process, and therefore carbon black is classified by manufacturing process.

The furnace black process uses heavy aromatic oils as feedstock. The production furnace uses a closed reactor to atomize the feedstock oil under carefully controlled conditions (primarily temperature and pressure). The primary feedstock is introduced into a hot gas stream (achieved by burning a secondary feedstock, e.g., natural gas or oil) where it vaporizes and then pyrolyzes in the vapor phase to form microscopic carbon particles. In most furnace reactors, the reaction rate is controlled by steam or water sprays. Residual gas, or tail gas, from a furnace reactor, includes a variety of gases such as carbon monoxide and hydrogen.

These residual gases contain a huge amount of heat in them, thus to achieve the highest process efficiency it is advisable to conserve this energy. Installing the waste heat recovery system along with the steam turbine in Carbon black industry meets the power & steam requirements of the plant. These residual gases are burnt to produce the steam which runs the turbine to generate power.

Carbon black industries need steam turbines for Drive applications and Power generation. Steam turbines may use to power the fan in the carbon black-producing furnace. also condensing steam turbines can be used specifically to generate power through a waste heat recovery system.

Turtle turbines have a variety of steam turbines to match the power needs of the carbon black industry.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.