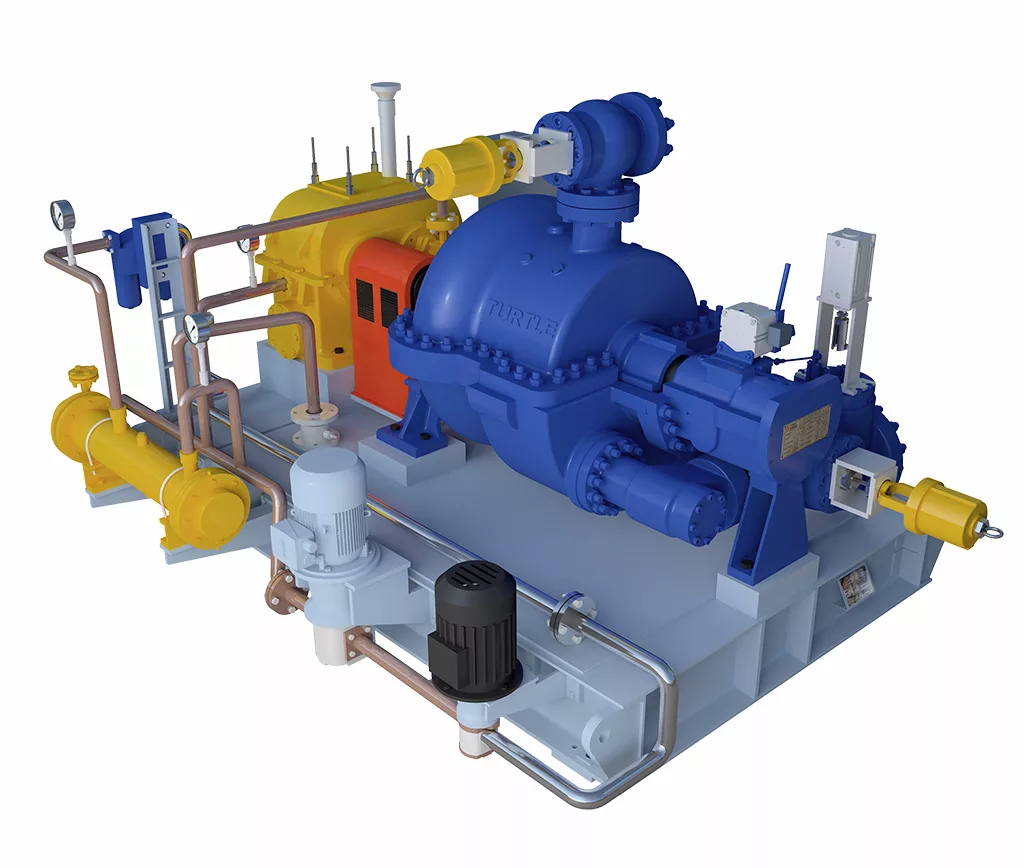

Steam turbine is the machine which extracts thermal energy from the steam and converts it to mechanical work on a rotating output shaft and then into electric energy with the help of alternator. The world of steam turbine manufacturing, uncovering the precision, innovation, and craftsmanship that make them an indispensable part of our modern lives.

The Manufacturing Process:

The range of potential processes and tools that can be applied to manufacture the steam turbine. Following are the processes which used for the steam turbine manufacturing. Design and Engineering: In steam turbines manufacturing engineers use advanced software and simulation tools to model the turbine’s performance and efficiency.

Factors such as rotor design, blade shapes, and material selection are critical to optimizing the turbine’s performance.

Precision Machining: Steam Turbine Manufacturing demands precision machining. Large rotors and blades, often made of high-strength materials like stainless steel or titanium, require specialized equipment and skilled craftsmen.

CNC machines ensure the highest level of accuracy, shaping components to tolerances measured in microns.

Quality Control: Quality control is paramount in steam turbine manufacturing. Every component undergoes in testing to ensure it meets strict quality standards.

Non-destructive testing techniques like ultrasonic and magnetic particle inspections detect even microscopic defects.

Assembly:

In steam turbine manufacturing, assembling is a complex process. Components, sometimes weighing several tons, are assembled with precision to create the rotor and casing.

The assembly process includes meticulous alignment and balancing to ensure the turbine operates smoothly.

Testing and Calibration: In steam turbine manufacturing,

prior to installation, each steam turbine undergoes extensive testing and calibration. This includes running the turbine at varying loads and speeds to verify its performance.

Testing ensures that the turbine can withstand the extreme conditions it will encounter in the field.

Innovations in Steam Turbine Manufacturing: Advanced Materials: In steam turbine manufacturing,

the use of advanced materials like nickel-based superalloys and composite materials allows for higher efficiency and durability.

These materials can withstand extreme temperatures and pressures, enhancing the turbine’s performance.

Digitalization: Digital technologies play a crucial role in modern steam turbine manufacturing. Computer-aided design (CAD) and simulation software optimize designs, while sensors and data analytics enable real-time monitoring and predictive maintenance.

Environmental Considerations: In Steam turbine manufacturing, manufacturers increasingly focused on sustainability. Efforts are made to reduce energy consumption during manufacturing and to design turbines that operate efficiently and emit fewer greenhouse gases.Turtle Turbines manufacturers the steam turbines from the range of 50kW to 3000kW. Turtle Turbines supplies steam turbine in the world.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com