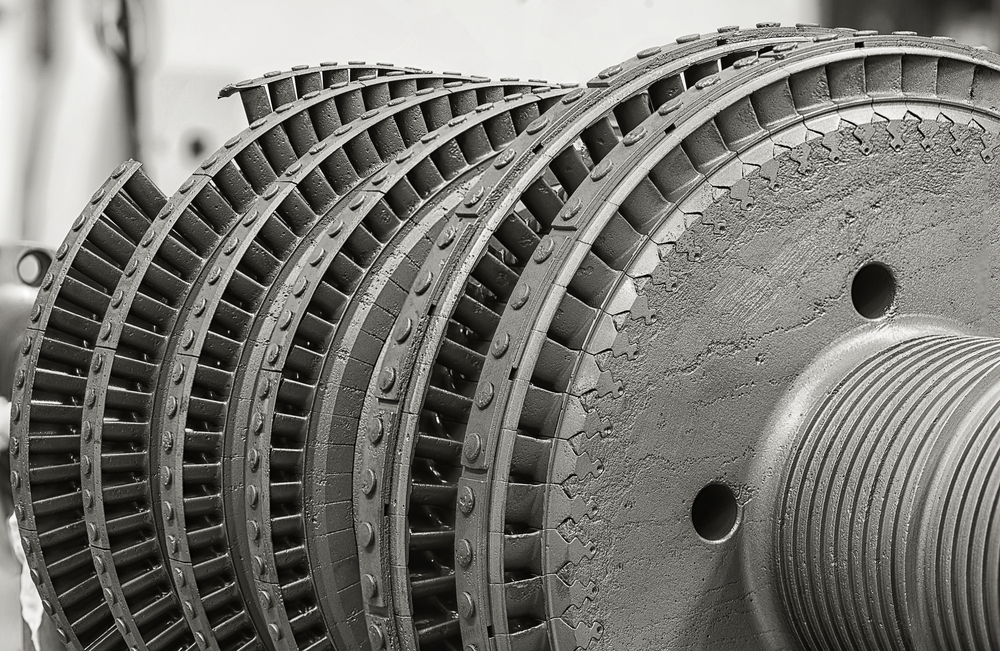

While setting up the process industry, buying capital equipment is a very important task. Most critical being the process equipment, boiler, turbine, civil work, etc. These are the major investments for setting up any process industry. To cut down the cost or when the budget is low often customer thinks of buying used steam turbines / secondhand steam turbines. The steam turbine is a very important piece of equipment for any process industry because it generates power at a very low cost when the steam is being utilized in the process and plays an important role when the local power is not available.

Used steam turbines are available in the market and are usually sold by the agencies engaged in servicing steam turbines. Usually, design data of such user second-hand steam turbines are not available to the service agency. In such situations, it is very easy to make the mistake of picking up the wrong turbine which ends up not delivering the desired outcomes. During such time, the Customer usually invests a huge amount of monies towards civil foundations, Steam, allied piping, and electrical accessories. When such turbines fail, without any fallback to the OEM supplier and with limitations on part of the turbine services agency, the entire investment is lost. Another problem arises when the steam turbine needs spares and service. As a Turbine OEM company not being involved in the purchase process or in servicing getting spares available is a very difficult task. The downtime may lead to huge losses. Also, the turbines are not being attended to by the OEM, the plant personnel has to put their special attention to running the turbine, hence it’s a tough and challenging task, that also adds to the operating cost.

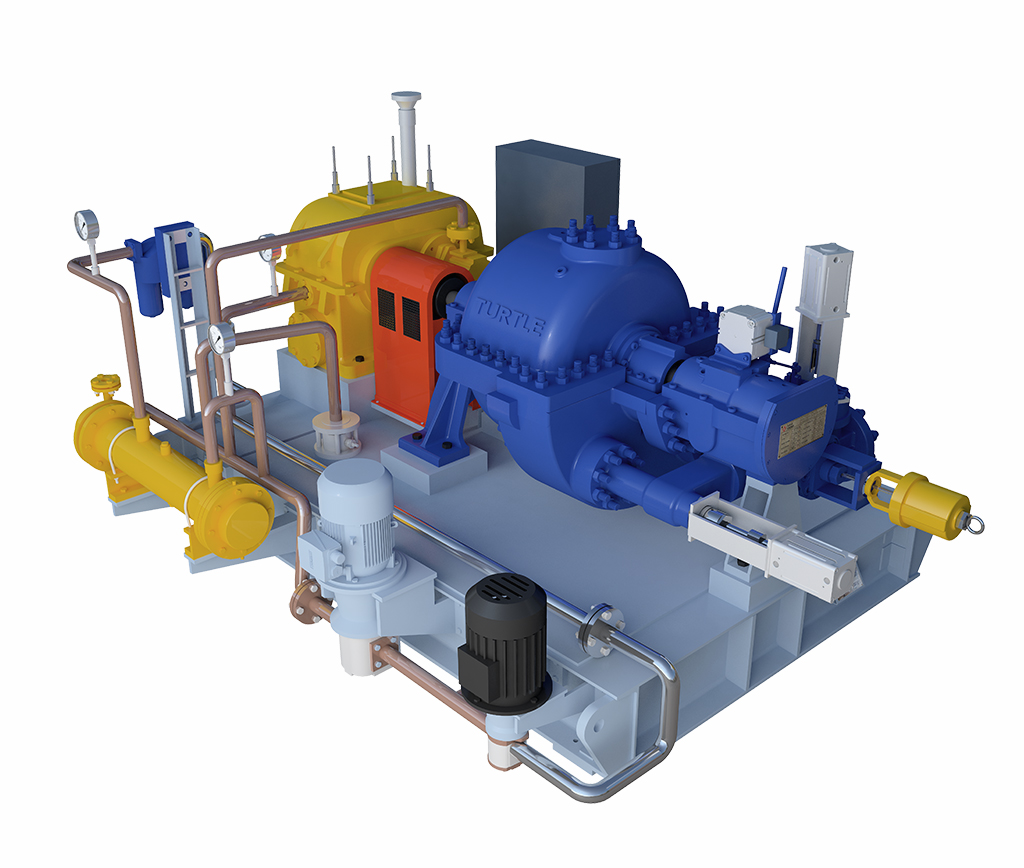

Investing in a new Steam Turbine provides short-term and long terms benefits. It is wise to invest a little more money than spend huge sums of money as expenses towards operating and maintaining used second-hand steam turbines.