Steam Turbines are used to Drive equipment such as Generators, Blowers, Pumps, etc. To Start the Turbine in a specific manner by bringing it to its operating Speed, Maintaining the Rated Speed on varying load conditions, and operating the Turbine at different Process Conditions e.g. Power Generation by Turbine, Exhaust Steam Pressure, Inlet Steam Pressure, Mains Power Exchange; a Control Device is used- Turbine Governor.

These Turbine Governors are categorized based on the Application such as:

- Mechanical Governors

- Electronic Governors

Based on the Specific Application. A Turbine used to Drive a Pump Blower can employ a Simple Mechanical Governor which is coupled to the Turbine Shaft to measure the Operating Speed. The Flyball mechanisms and the linkages together control the Steam Inlet to the Turbine to maintain the Speed at Varying Load Conditions.

When there is more than one parameter to be controlled and Turbine Start-Up is more complex, such as in the case of Multistage Turbines which drive Electrical Generators, Electronic Governors are employed. Electronic Governors use Sensors to measure Turbine Speed, Steam Pressure, Power, etc. These governors can be programmed to carry out Controlled Start-Up of the Turbine in predefined Ramp rates, Carry out synchronization of Generator with Local Grid, Maintain the Process Steam demands and Power generation Demands. An electronic Governor uses in conjunction with Electro-Hydraulic Actuators to Contro the Inlet steam of the Turbine.

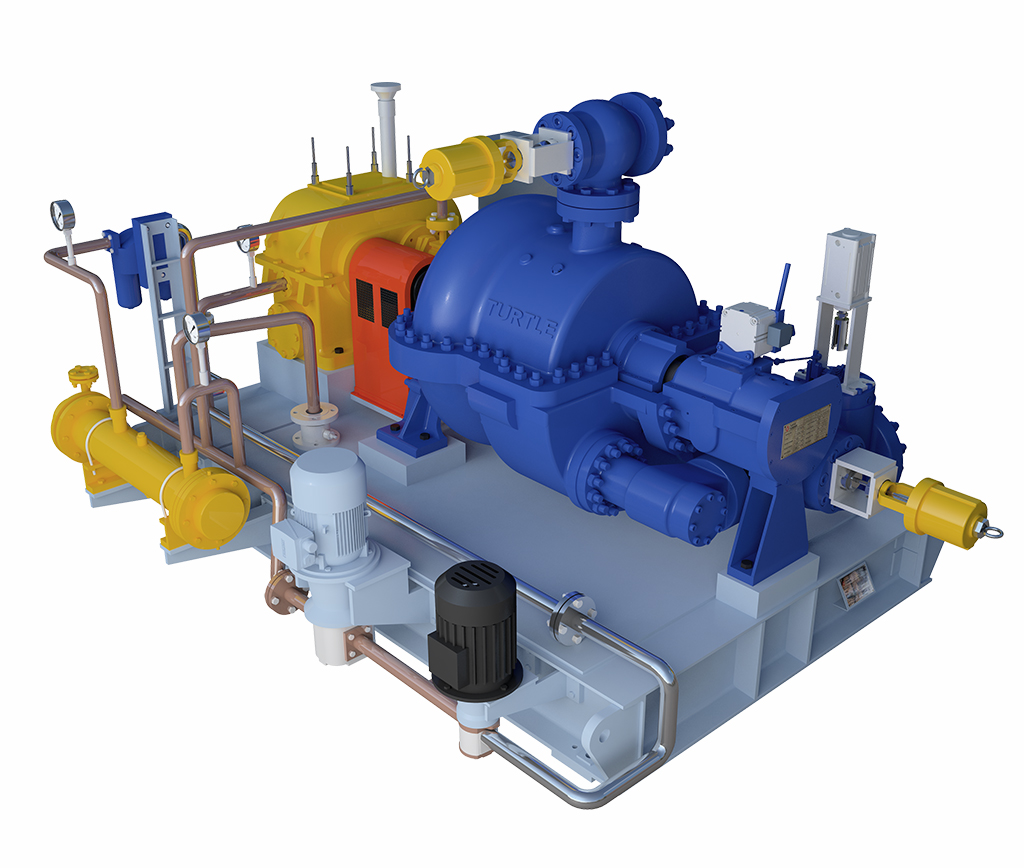

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.