Back pressure turbines can either be single-stage or multi-stage which are often used in industrial plants, the turbine serves as a reducing station between the boiler and the process steam header.

Back-pressure steam turbines or non-condensing turbines are most widely used for process steam applications. Steam is a principal energy source for many industrial processes. Using steam as an energy source has many advantages high heat capacity, transportability, low toxicity

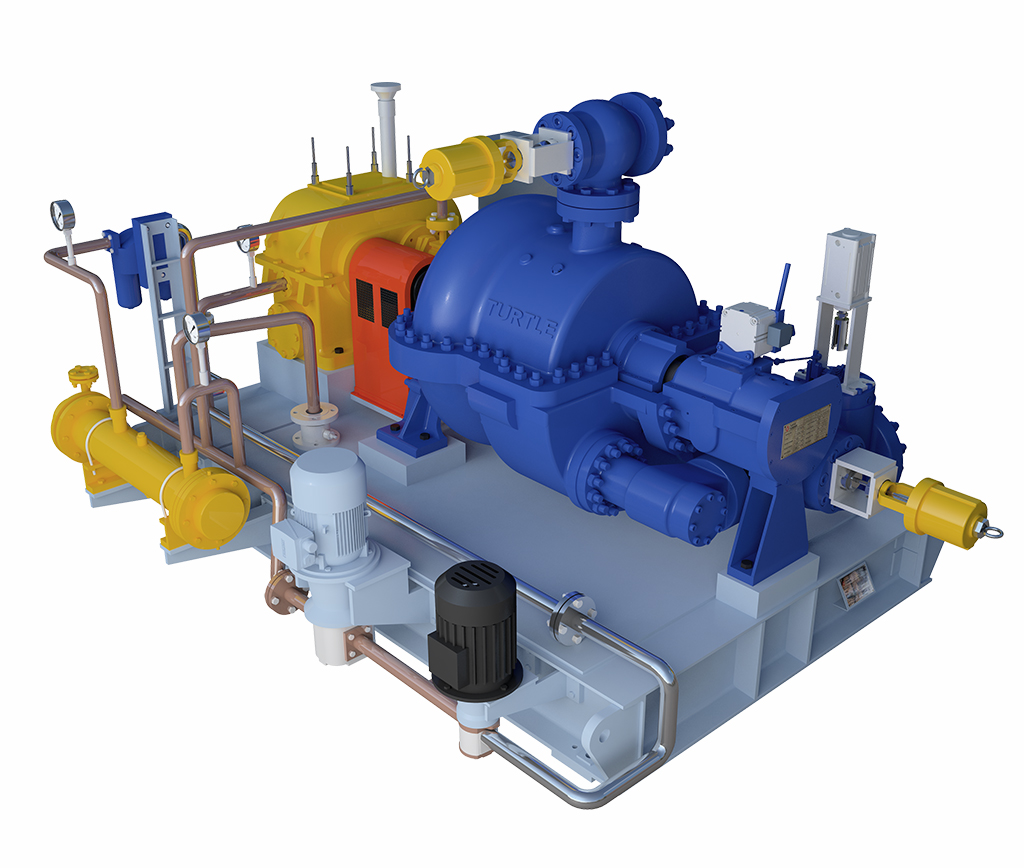

The process steam can be produced by back-pressure steam turbines, which also generate mechanical work (or electrical energy). Back-pressure turbines expand the live steam supplied by the boiler to the pressure at which the steam is required for the process. A regulating valve controls the exhaust pressure to suit the needs of the process steam pressure. Back-pressure turbines are commonly found at refineries, district heating units, pulp and paper plants, and desalination facilities where large amounts of low-pressure process steam are needed. The electric power generated by the back-pressure turbine is directly proportional to the amount of process steam required.

A back pressure Turbine is the best suitable option for Cogeneration or Energy Conservation. It reduces the grid dependency without hampering the process with a very marginal increment in fuel cost.

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.