Micro steam turbines are becoming increasingly popular in Australia as a solution for small-scale power generation. Micro Steam Turbines in Australia offers several advantages over traditional power generation methods, including high efficiency, versatility, and cost-effectiveness. There is good potential for micro steam turbines in Australia.

Advantages of using micro steam turbines in Australia:

- Decentralized power generation: Micro steam turbines can be used in decentralized power generation systems, providing power to small communities and remote locations in Australia.

- Waste heat recovery: Micro steam turbines can be used to recover waste heat from industrial processes and convert it into usable electricity, reducing energy costs and emissions.

- Renewable energy integration: Micro steam turbines can be integrated into renewable energy systems, such as geothermal and biomass power plants, to generate electricity.

- CHP: Combined heat and power (CHP) systems can use micro steam turbines to generate both electricity and heat, improving overall energy efficiency.

Applications of micro steam turbines in Australia:

- Industrial processes: Micro steam turbines can be used in industrial processes to recover waste heat and generate electricity.

Remote communities: Micro steam turbines can provide power to remote communities that are not connected to the main grid. - Agriculture: Micro steam turbines can be used on farms to generate power from biomass, such as waste from crops and livestock.

- Mining: Micro steam turbines can be used in mining operations to generate power from waste heat.

In conclusion, micro steam turbines are a cost-effective and efficient solution for small-scale power generation in Australia. They offer a variety of advantages, including decentralized power generation, waste heat recovery, renewable energy integration, and CHP. These factors make micro steam turbines a viable option for a range of applications, including industrial processes, remote communities, agriculture, and mining.

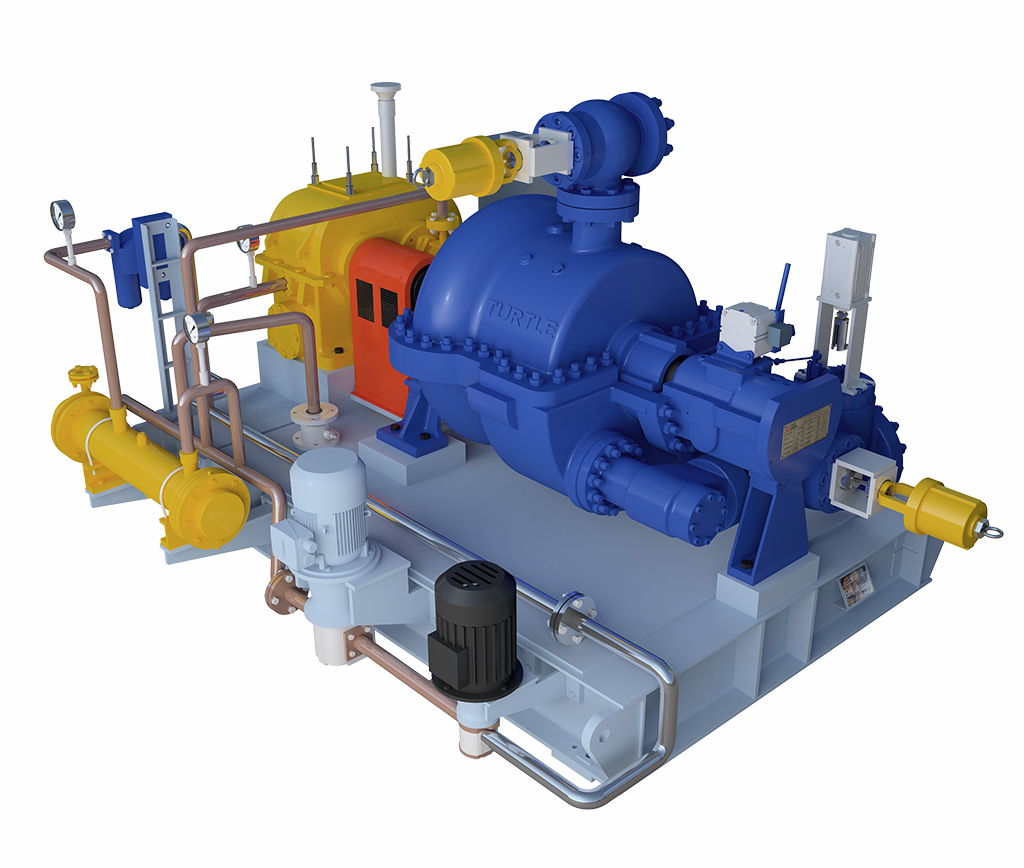

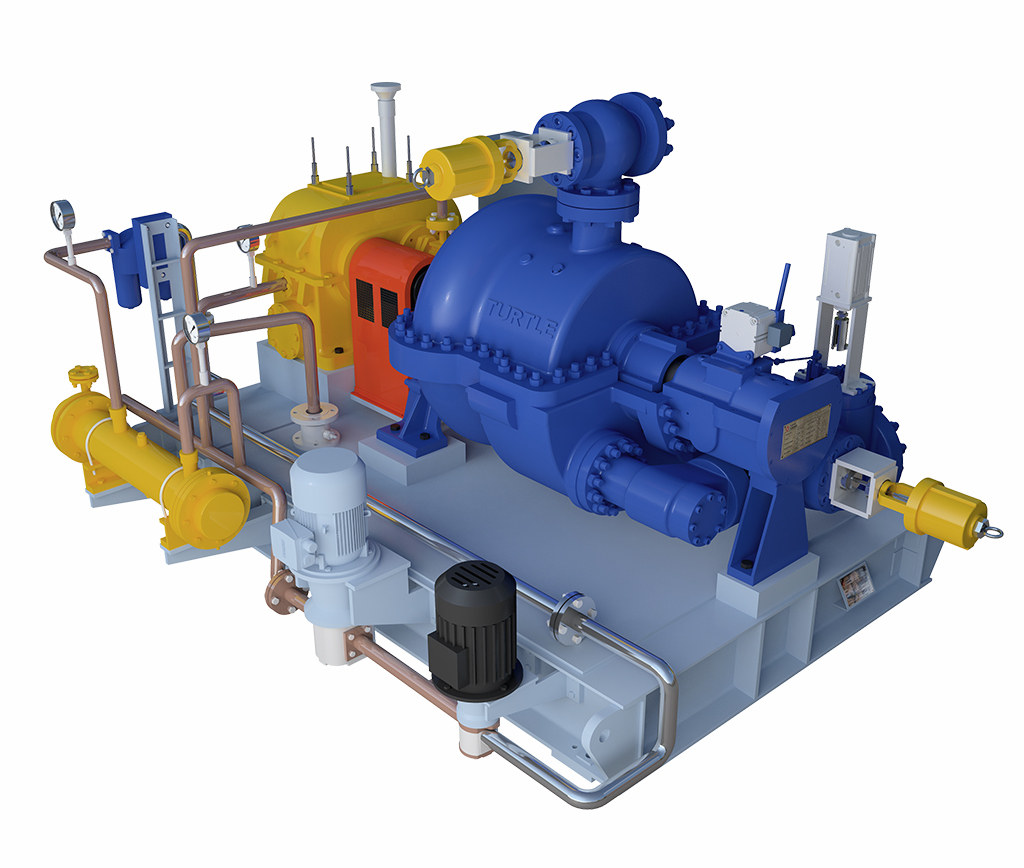

We at Turtle Turbine offer Micro Steam Turbines from 100 kW to 3000 kW for such applications, which are Reliable, Robust, and Intelligent.