According to a Survey, Electrification in the Philippines stands at 85%. That means 15% people of people don’t have access to electric bulbs. High-Pressure Turbines in the Philippines are not new and can contribute to Power Generation and improve Power Generation in the Philippines.

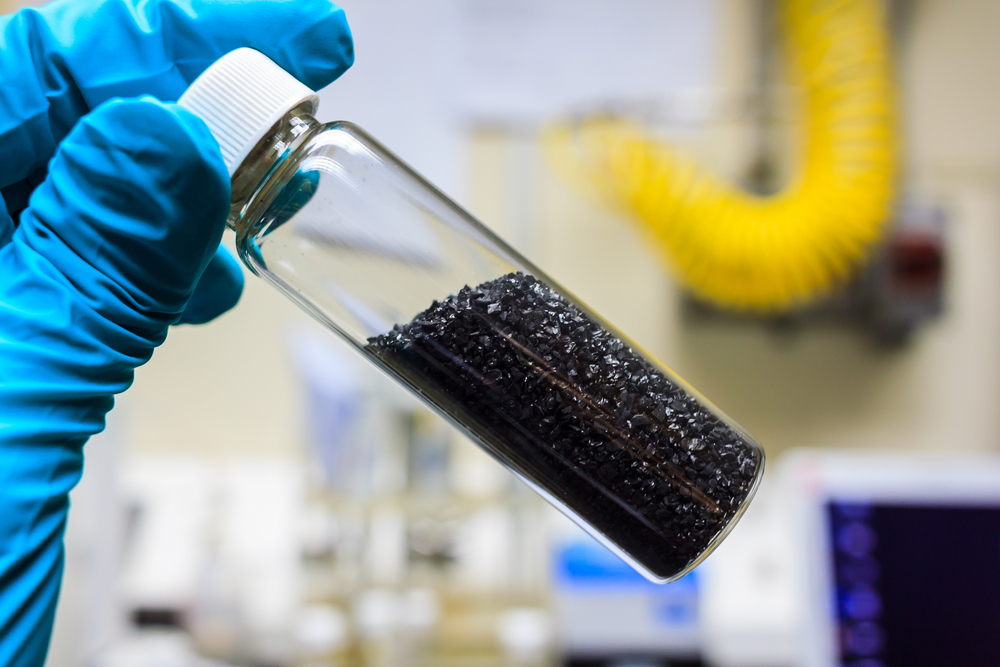

High-Pressure Turbines in the Philippines have been working with Steam Boilers that run on Rice Husk. The Philippines is an island country Rice Husk is largely available. High-Pressure Turbines in the Philippines have contributed to Power for the Industrial Sector which also needs steam for their Process.

High-Pressure Turbines in the Philippines have largely contributed over the years in making available onsite power at lower utility power costs. Various Industries in the Philippines which need Steam for Process can utilize the steam coming from these High-Pressure Steam Turbines which work in Back Pressure, extraction Condensing modes to generate On-site Power for industry and contribute to the Power demand of the Philippines to relieve the National grid from Power Demands to make it available for others in need.

Turtle Turbines with experience of more than 20 years in Steam Turbines has been supplying High-Pressure Steam Turbines with installations in South East Asia including the Philippines, Thailand, Vietnam India, and African Countries in more than 18 different Industry Segments.